Bottom Entry Mixers

Bottom Entry Mixers

Silverson’s hygienic series of high shear Bottom Entry mixers are designed to fit into the bottom or side of a mixing vessel. These high shear mixers are typically used in conjunction with a slow speed anchor stirrer or scraper unit for high viscosity products. The Silverson Bottom Entry mixer gives high shear homogenisation while the stirrer/scraper distributes the homogenised output uniformly through the vessel. This is ideal for high viscosity cosmetic, pharmaceutical and food products.

Bottom Entry mixers can also be used by themselves on low viscosity products and to wet out powders. Silverson Bottom Entry mixers offer full compliance with cGMP and USDA requirements.

How It Works

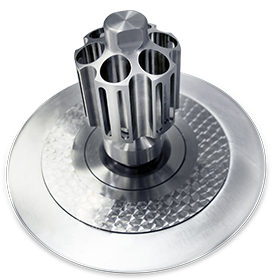

The advantages of Silverson’s Bottom Entry mixer over simple conventional stirrers or agitators stem from the multistage mixing/shearing action as materials are drawn through the specially designed Silverson workhead - the heart of every machine.

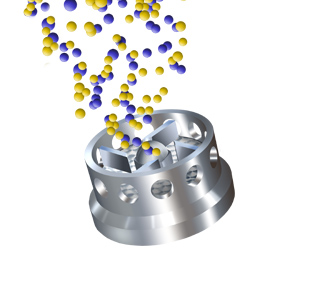

The high speed rotation of the rotor blades exerts a powerful suction, drawing liquid and solid materials downwards into the center of the workhead.

Centrifugal force then drives the materials towards the periphery of the workhead where they are milled in the clearance between the rotor and the stator.

The materials are subjected to intense hydraulic shear as they are forced out through the stator and projected radially at high speed towards the sides of the mixing vessel. Fresh material is simultaneously drawn into the workhead, maintaining the mixing cycle.

-

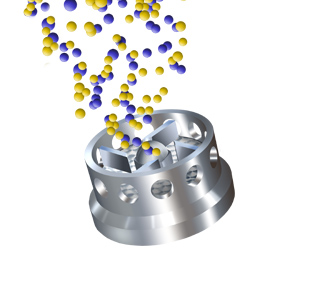

Stage 1

Stage 1

The high speed rotation of the rotor blades exerts a powerful suction, drawing liquid and solid materials downwards into the center of the workhead.

-

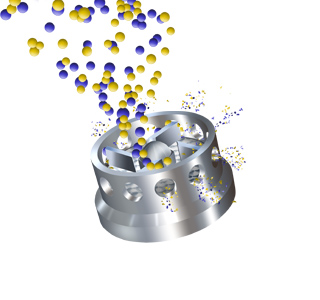

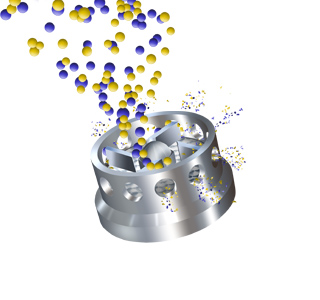

Stage 2

Stage 2

Centrifugal force then drives the materials towards the periphery of the workhead where they are milled in the clearance between the rotor and the stator.

-

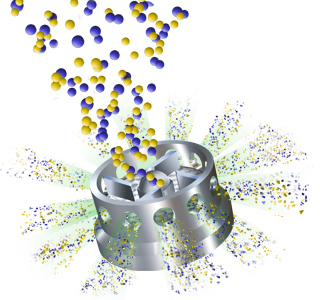

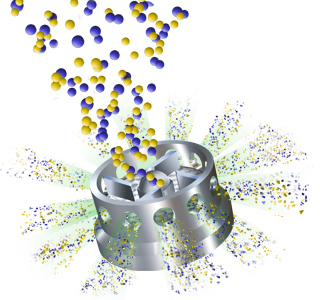

Stage 3

Stage 3

The materials are subjected to intense hydraulic shear as they are forced out through the stator and projected radially at high speed towards the sides of the mixing vessel. Fresh material is simultaneously drawn into the workhead, maintaining the mixing cycle.

Videos

Bottom Entry Mixer

Mixer Options

Workheads

Technical Information

- Capacity

- 5 - 7000 litres.

- Materials of Construction

- All wetted parts in 316L stainless steel. Special material on request.

- Motor Specifications

- TEFV and ATEX approved Flameproof motors are available as standard. Inverter rated, stainless steel and other motors are available as optional extras.

- Mounting

- Stainless steel circular flange fitted as standard.

- Sealing

- Single or double mechanical shaft seals available as standard.

- Operating Pressures

- From full vacuum up to 150psi (10 Bar). Higher pressure units are available on request.

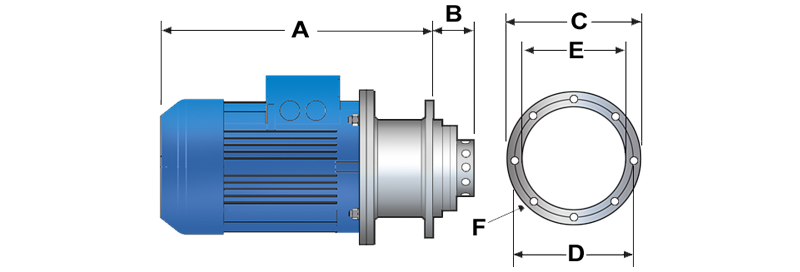

| kW | R.P.M | TEFV A | EExD A | B | C | D | E | F | |

|---|---|---|---|---|---|---|---|---|---|

| BE243 | .75 | 3000 | 320 | 322 | 67 | 152 | 127 | 102 | 6x11 |

| BE275 | 1.1 | 3000 | 312 | 318 | 77 | 210 | 178 | 128 | 6x14 |

| BE387 | 2.2 | 3000 | 372 | 383 | 80 | 267 | 241 | 190 | 8x14 |

| BE425 | 4 | 3000 | 432 | 443 | 83 | 267 | 241 | 190 | 8x14 |

| BE450 | 7.5 | 3000 | 512 | 520 | 99 | 267 | 241 | 197 | 8x14 |

| BE500 | 15 | 3000 | 605 | 605 | 113 | 305 | 267 | 197 | 8x17 |

| BE600 | 22 | 3000 | 667 | 672 | 120 | 305 | 267 | 216 | 8x17 |

The dimensions shown are approximate only and certified diagrams should be used for installation

purposes. Silverson reserves the right to change dimensions and specifications without notice.