Cannabidiol Oil (CBD) in food products

Cannabidiol, also known as CBD, is an oil derived from cannabis. It contains none of the psychoactive ingredients tetrahydrocannabinol (THC), so there is no 'high' from it.

CBD is claimed to have many health benefits such as reducing inflammation, pain relief and reducing anxiety.

The incorporation of CBD into foods is becoming one of the fastest growing trends in the process industry. A variety of different products such as beverages, gummies, snacks and baked foods containing CBD oil are now available. Silverson mixers are increasingly being used for R&D and small scale production in this emerging market.

The Process

CBD is mostly supplied in liquid form, and depending on concentration can be a highly viscous liquid.

Because of the wide range of products, processing varies depending on the product type and ingredients used. However, similar processing requirements must be met:

- The mixing system must be capable of blending liquids of widely different viscosities.

- It must also be capable of finely and uniformly dispersing the oil into the aqueous phase in emulsions.

- Production must be consistent between batches to ensure the amount of CBD oil in the product does not exceed guidelines. CBD oil products must be potency tested so repeatability is important.

- Processing is often carried out at raised temperatures, normally between 50 - 80°C (120 - 150°F) to reduce viscosity, and aid dissolving of sugars, formation of emulsions, etc.

- All food products must adhere to food safety regulations and FDA guidelines and process equipment must be able to meet these standards.

The Problem

- Depending on concentration, CBD oil can be a highly viscous liquid which can be difficult to blend with water or low viscosity oils such as vegetable oil or coconut oil. With conventional agitators “stratification” can occur, where the two liquids form layers of globules rather than blending together. Long mixing times may be required to achieve uniformity.

- Conventional mixers do not produce sufficient shear to finely and uniformly disperse the oil into aqueous systems for beverages and other emulsion products.

- Beverages and gummies can appear cloudy rather than clear if droplet size is not reduced sufficiently.

- Many powdered functional ingredients are difficult to disperse and hydrate, especially gelling and stabilising agents. Conventional mixers cannot readily break down agglomerates and this adversely affects product quality, uniformity and batch to batch consistency.

- Heating the mix adds to process time and costs.

- Many conventional mixers and agitators cannot be scaled up to production scale easily, failing to keep up with business growth and customer demand.

The Solution

These problems can be overcome by using a Silverson high shear mixer. Operation is as follows:

Stage 1

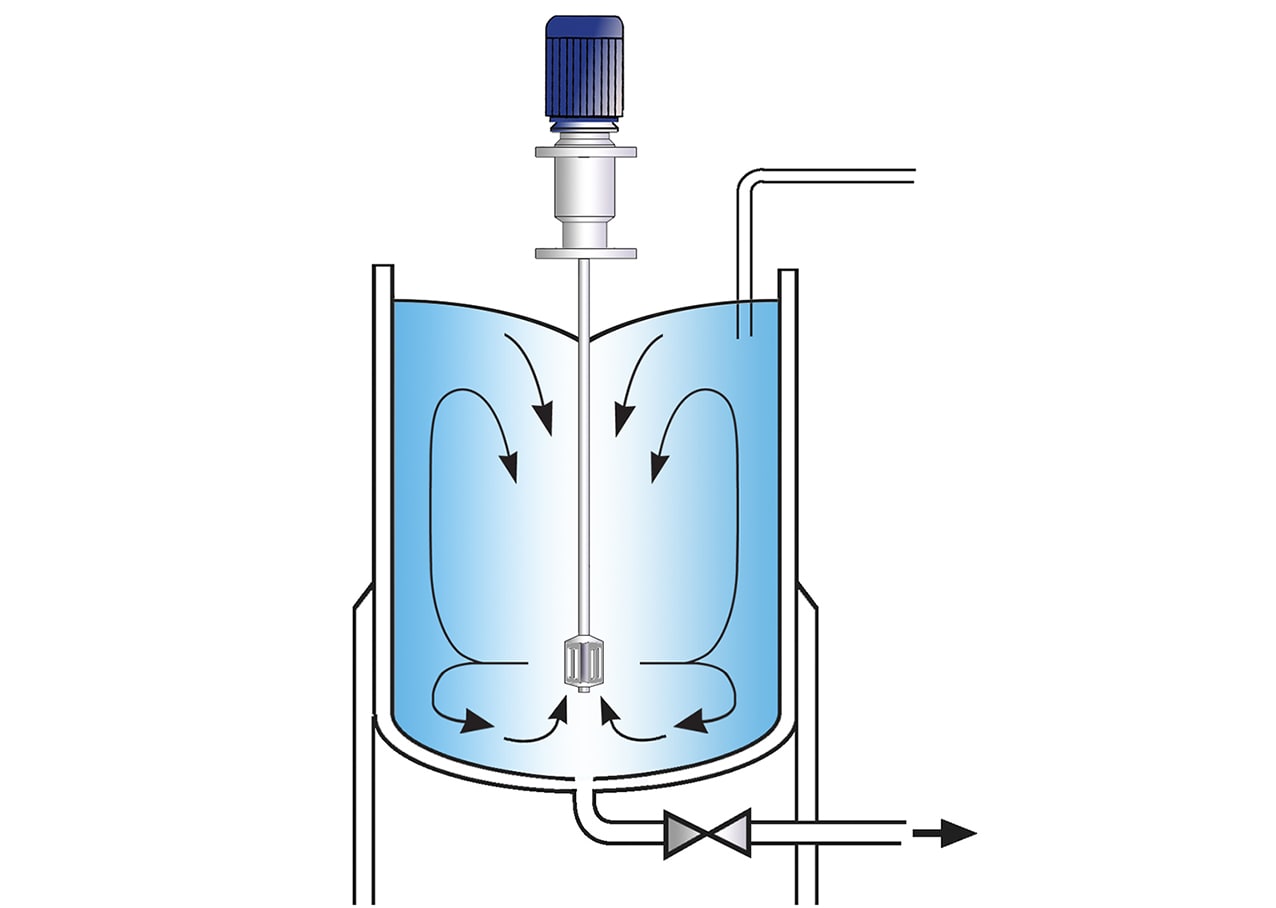

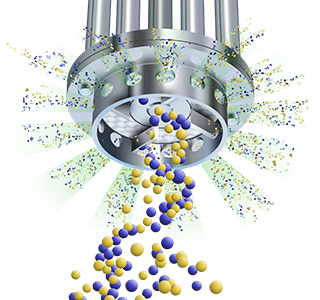

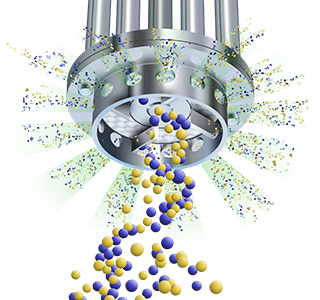

The high speed rotation of the rotor blades creates a powerful suction which draws liquids and any solid or powdered ingredients into the workhead.

Stage 2

The materials are subjected to intense shear within the workhead. Any agglomerates that may have formed are broken down in the gap between the rotor and stator.

Stage 3

The product is forced out through the stator as fresh material is drawn in. Particle size is progressively reduced producing a stable and homogeneous emulsion.

-

Stage 1

Stage 1

The high speed rotation of the rotor blades creates a powerful suction which draws liquids and any solid or powdered ingredients into the workhead.

-

Stage 2

Stage 2

The materials are subjected to intense shear within the workhead. Any agglomerates that may have formed are broken down in the gap between the rotor and stator.

-

Stage 3

Stage 3

The product is forced out through the stator as fresh material is drawn in. Particle size is progressively reduced producing a stable and homogeneous emulsion.

The Advantages

- Droplet size can be reduced down to 2 - 5 microns. Smaller droplet sizes have been shown to absorb faster during digestion, leading to the effects of the active cannabis ingredient being more immediate.

- The fine dispersion also ensures a stable emulsion is obtained.

- Any powdered ingredients added into the mix are quickly dispersed, resulting in an agglomerate-free dispersion.

- Repeatability and batch-to-batch consistency is guaranteed.

- Mixing can often be done at ambient temperature, saving time and money. For example, a Silverson mixer can produce a 66 Brix sugar solution at ambient temperature.

- Ultra-hygienic models available to meet FDA and other food processing requirements.

- Silverson Laboratory mixers can easily be scaled up to production scale equivalents as each Silverson mixer is engineered to the same fine tolerances.

Silverson has a wide range of mixing equipment suitable for this application which can easily be scaled up from Laboratory to production scale to keep up with customer demand.

Silverson Laboratory Mixers

- Suitable for batch sizes of up to 12 litres

- Built to the same tolerances as production models, providing easy and accurate means of scaling up

- Interchangeable workheads allow the unit to be adapted for a range of laboratory applications

- Several instrumentation options are available, including tachometers and ammeters

Silverson AX Series Laboratory Mixer

- Features generally as Laboratory mixer above

- Suitable for batches of up to 50 litres, depending on viscosity

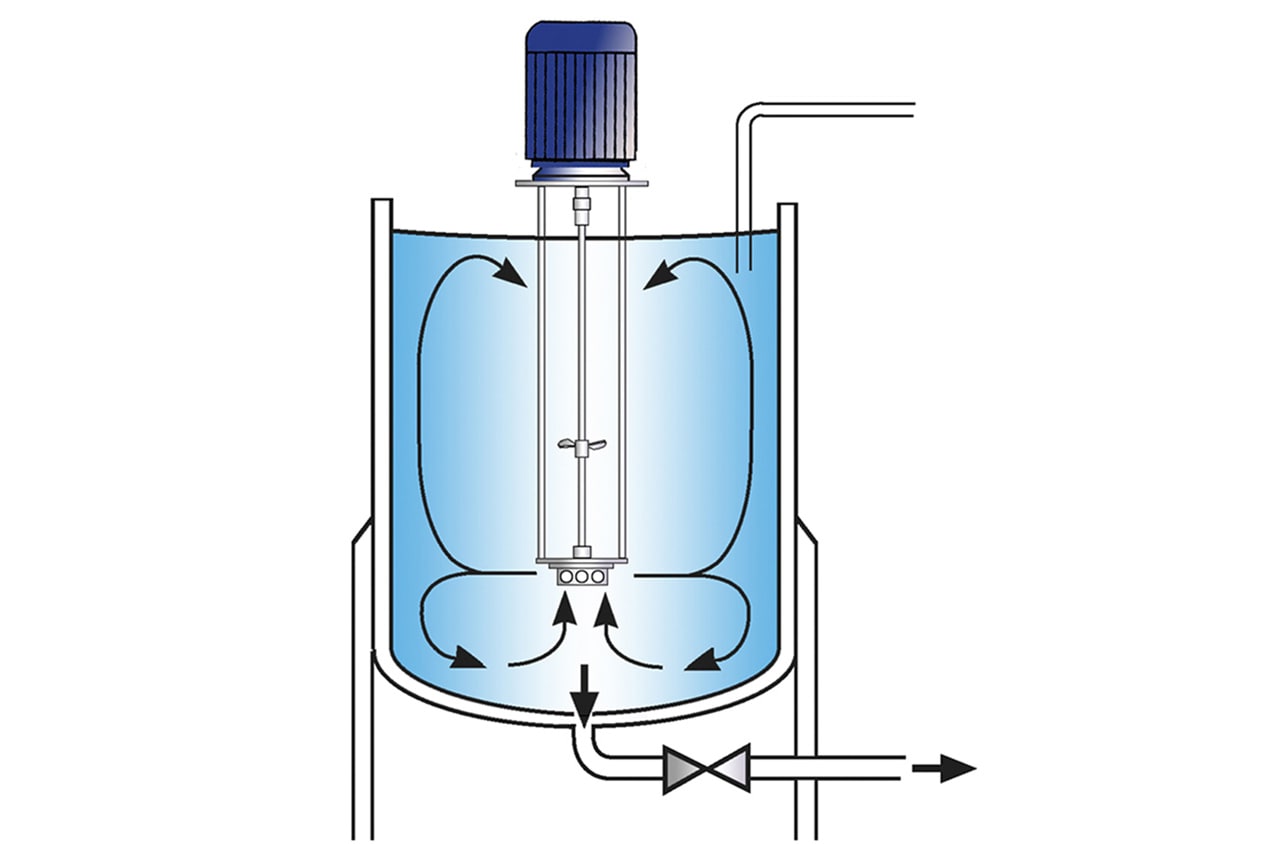

Silverson Ultramix

- Suitable for higher viscosity mixes

- Capable of incorporating powdered ingredients

- Ultra Hygienic design

Silverson Batch Mixers

- Suitable for batches up to 1000 litres

- Can be used on mobile floor stands allowing one mixer to be used for several products

- Small units available for R&D and pilot production

- Can be supplied with FDA documentation