Dispersion of Beer Foam Head Retaining Agents

Ingredients such as propylene glycol alginate (PGA) may be added to beer to stabilise the foam head and to aid resistance to breakdown of foam in the presence of detergent residues or grease on the glass.

The Process

PGA is dispersed in water (referred to as “liquor” in the brewing industry) before being added to the beer. A typical dispersion process using conventional mixers would be as follows:

- The vessel is charged with water.

- The mixer is started.

- The alginate is added gradually into the vortex and dispersed into the water.

- Mixing continues for up to an hour (depending on batch size) to ensure thorough dispersion.

- The solution is then left to stand for several hours to allow hydration to be completed.

- The mixer is run for a further period to ensure the solution is homogeneous.

- Pasteurisation may be carried out to destroy any microorganisms.

The Problem

Dispersion of this type of powder is one of the most difficult of all mixing operations. A number of problems are frequently encountered when using conventional mixers:

- PGA tends to agglomerate. Partially hydrated material on the outside of the agglomerate prevents dry particles inside from being exposed to the surrounding liquid and dissolved. Conventional agitators do not produce sufficient shear to break these down.

- Long mixing times are required to obtain the required dispersion/solution.

- Powder has to be added under controlled (labour intensive) conditions to prevent lump formation and scumline on the vessel.

- Once viscosity increase or gelling has started to occur, agitation of the solution and therefore dispersion of powder becomes increasingly difficult.

- Aeration must be avoided to prevent foaming, as owing to the nature of the product, the foam is difficult to disperse.

The Solution

By using a Silverson mixer, intermediate stages of production can be eliminated, product quality improved and processing times dramatically reduced as follows:

Stage 1

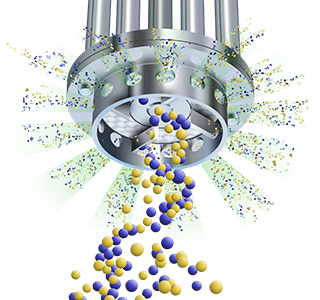

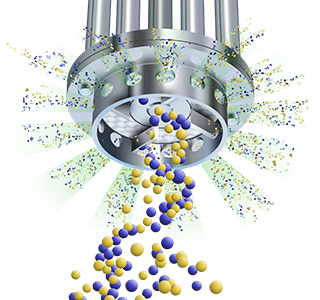

The vessel is charged with the required amount of water. The Silverson mixer is started and the alginate is added all at once as rapidly as possible. The high speed rotation of the rotors creates a powerful suction which draws the water and alginate particles into the workhead.

Stage 2

The materials are subjected to intense shear within the workhead. Any agglomerated particles are fully broken down in the clearance between the ends of the rotor blades and the stator wall. The product is then forced out through the stator and returned to the mix.

Stage 3

Fresh liquid and powdered ingredients are simultaneously drawn into the workhead, maintaining the mixing cycle. In a short time the product passes through the workhead many times, ensuring that thorough dispersion is rapidly completed.

-

Stage 1

Stage 1

The vessel is charged with the required amount of water. The Silverson mixer is started and the alginate is added all at once as rapidly as possible. The high speed rotation of the rotors creates a powerful suction which draws the water and alginate particles into the workhead.

-

Stage 2

Stage 2

The materials are subjected to intense shear within the workhead. Any agglomerated particles are fully broken down in the clearance between the ends of the rotor blades and the stator wall. The product is then forced out through the stator and returned to the mix.

-

Stage 3

Stage 3

Fresh liquid and powdered ingredients are simultaneously drawn into the workhead, maintaining the mixing cycle. In a short time the product passes through the workhead many times, ensuring that thorough dispersion is rapidly completed.

The Advantages

- Dramatically reduced mixing times.

- Rapid powder addition rate eliminates operator error.

- Consistent product quality.

- Agglomerate-free mix.

- Stable viscosity of end product.

- Thickening/gelling effect of the alginate is maximised.

- Reduced aeration and oxygenation due to shorter mixing times.

The Silverson mixer to be used is determined by the batch size, formulation, type of ingredients used and the viscosity of the end product:

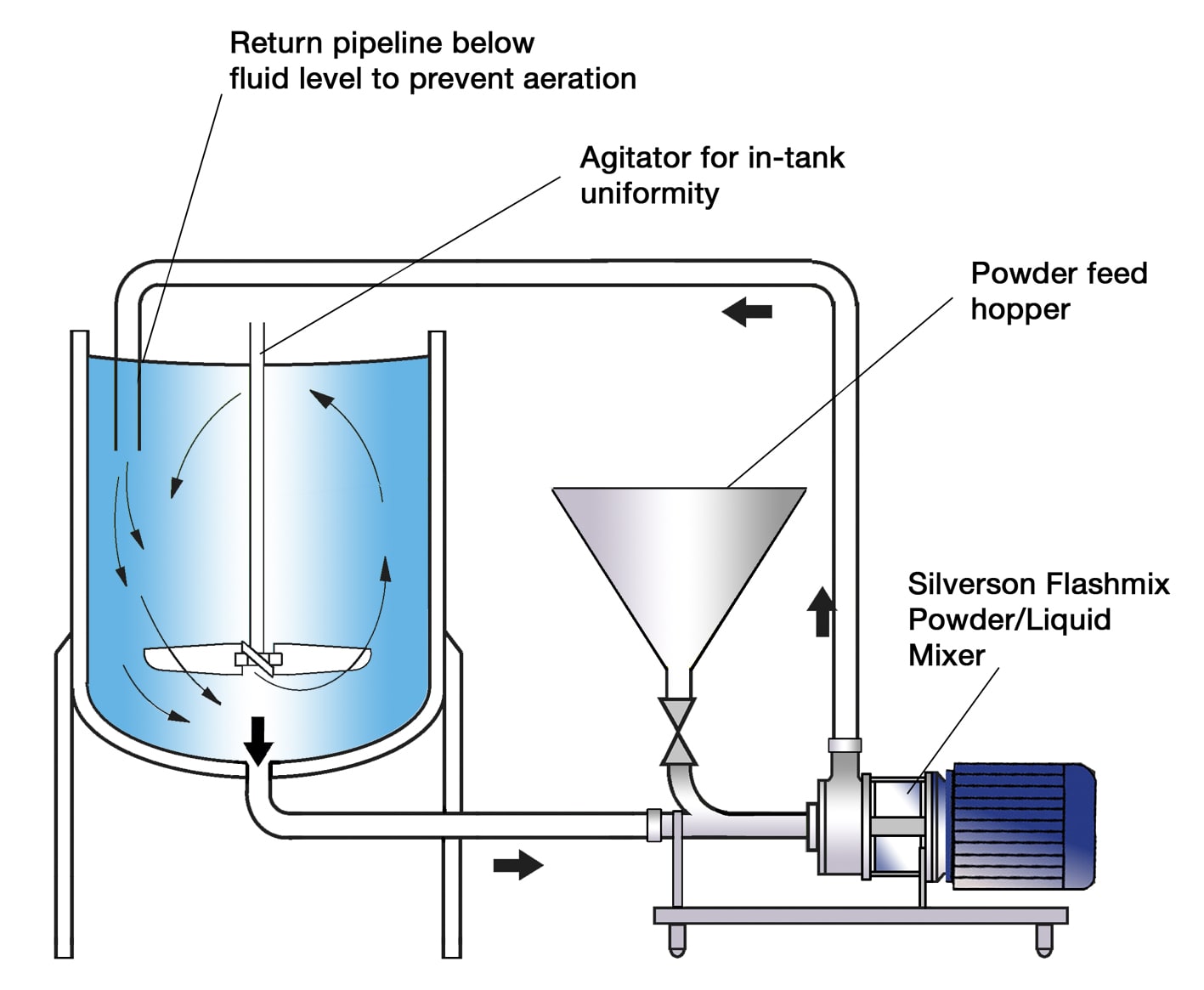

Silverson Flashmix

- Ideal for larger batches or repeated smaller batches

- Capable of rapidly incorporating large volumes of powders

- Minimised aeration

- Minimised cleaning requirements

- Suitable for higher viscosity mixes

- Suitable for operation at higher temperatures

- Controlled powder addition rate

- Minimum operator input required

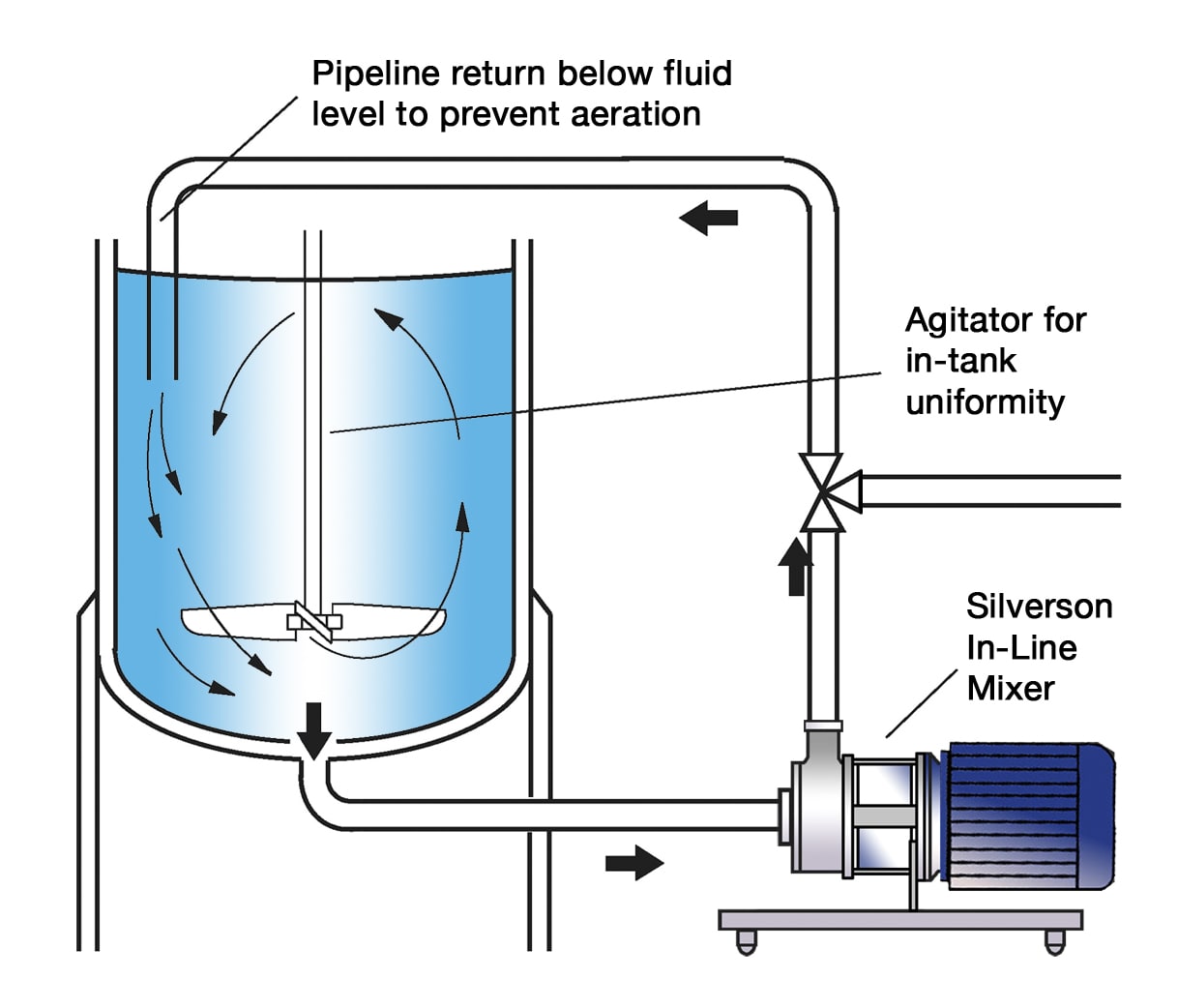

High Shear In-Line Mixers

- Easily retrofitted to existing plant

- Ideal for larger batches

- Aeration free

- Self-pumping

- Can be used to discharge vessel

- Ultra Hygienic models available

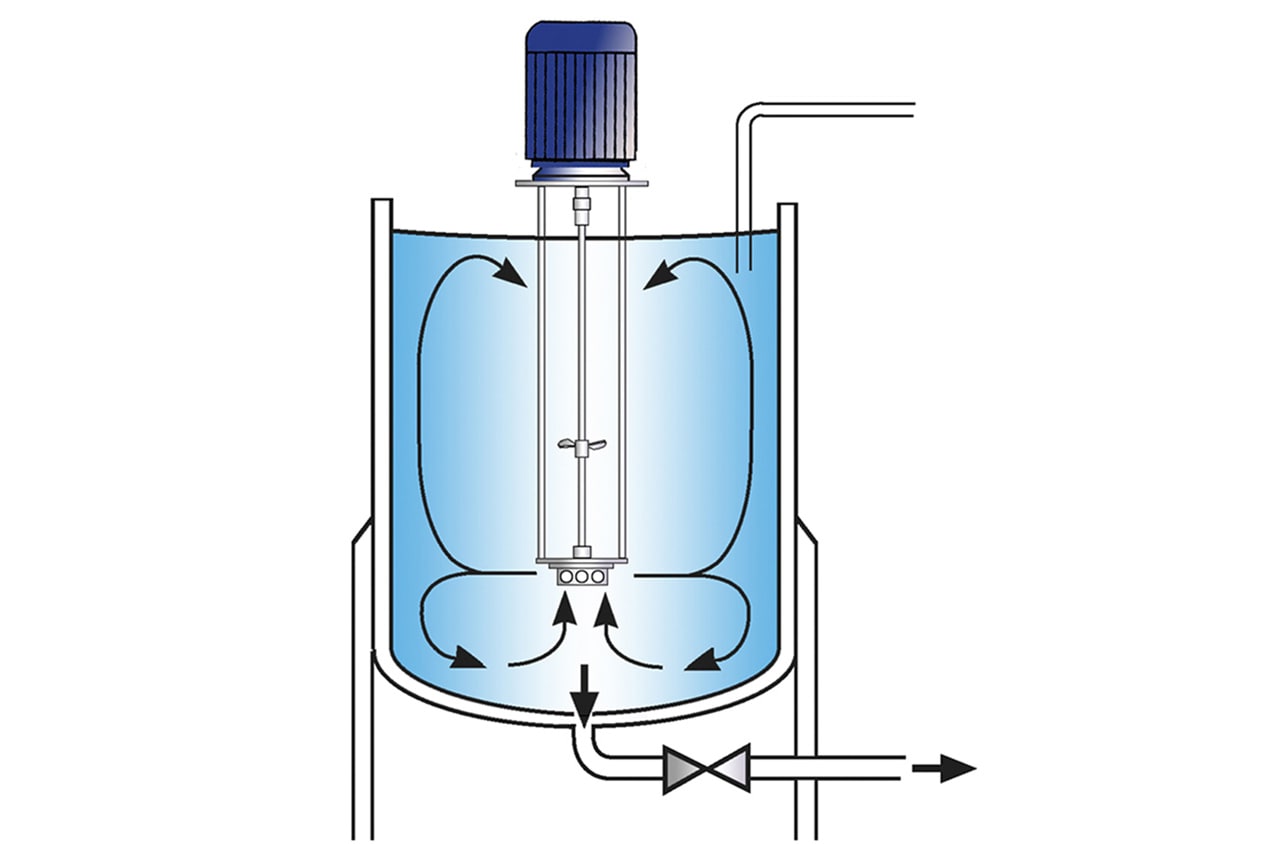

High Shear Batch Mixers

- Suitable for batches of up to 1000 litres

- Can be used on mobile floor stands

- Can easily be moved from vessel to vessel