Redispersion of Filter Cake

The solid material obtained from filtration or centrifugation of a suspension is called filter cake. This usually contains 60% or more solids in aqueous or organic media. Materials sometimes extracted in this way include:

- Pigments

- Dyestuffs

- Pharmaceutical active ingredients

- Detergent additives

- Optical brighteners

Image courtesy of CDE Global: www.cdeglobal.com

The Process

Filter cake requires redispersion into an appropriate solvent before use in subsequent manufacturing processes; it may also require dispersion into an appropriate “wash” fluid to remove traces of “mother liquor” or other impurities. Requirements of the redispersion process include:

- Breaking up of the cake into the surrounding liquid to form a slurry.

- Intimate contact of liquid and solid particles.

The Problem

Using conventional mixers and agitators a number of problems can be encountered:

- Long periods of soaking in appropriate aqueous or organic solvent are sometimes required to break up the cake.

- The filter or centrifuge cake is in the form of large lumps which conventional agitators cannot easily break down.

- Even after the cake has been reduced to smaller particles, conventional agitation will not break up clumps of individual agglomerates or crystals.

- Some filter cakes are hard with abrasive particles which can cause excessive wear to machinery.

- Mother liquor trapped in clusters and agglomerates may be a contaminant and require a further filtration or centrifugation step to eliminate.

The Solution

A Silverson High Shear mixer will easily break large lumps of cake and also disperse the individual particles or crystals into the surrounding liquid. This is achieved as follows:

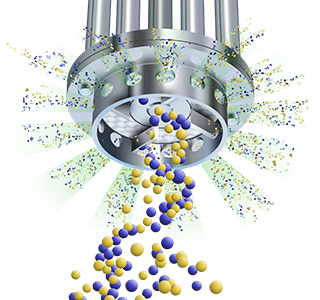

Stage 1

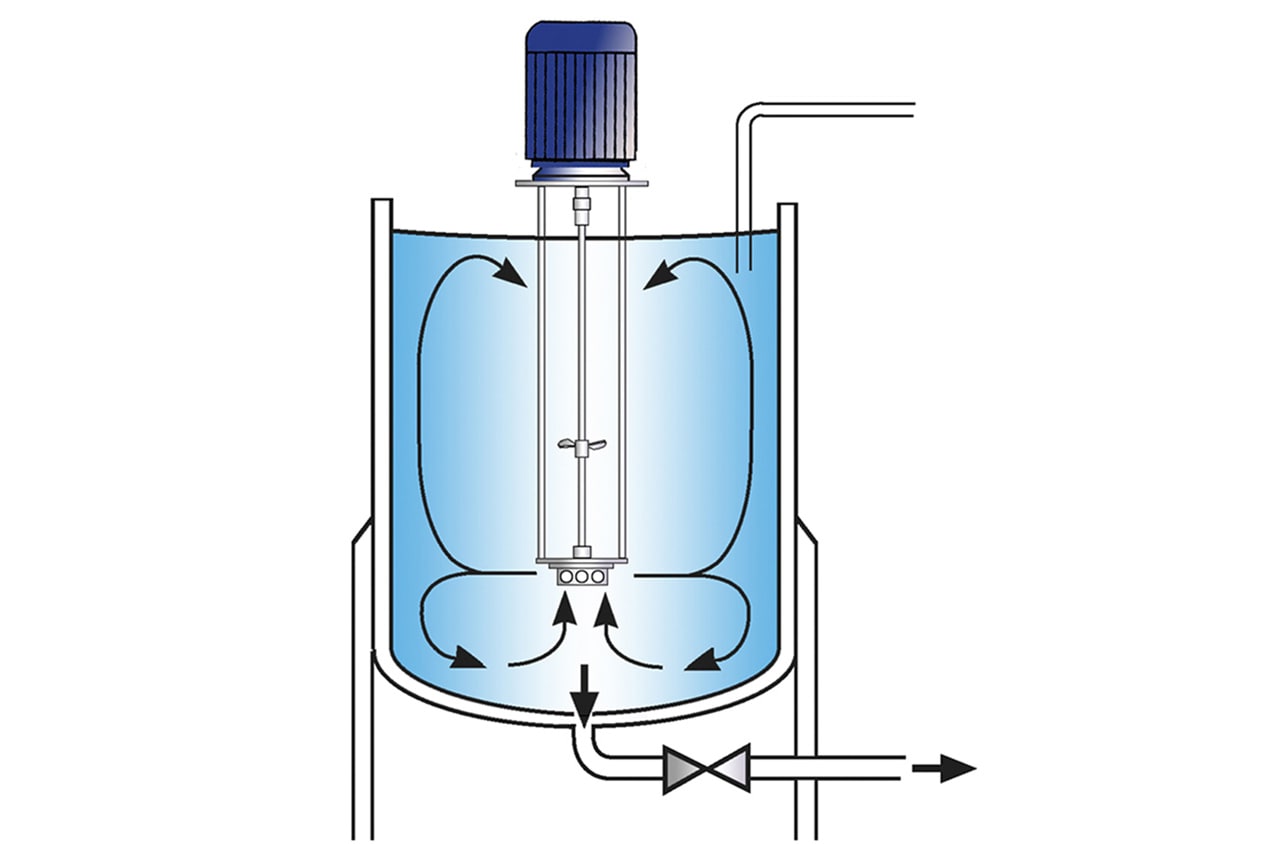

The vessel is charged with the aqueous or organic solvent. The mixer is started and the filter cake is added. The powerful vortex created by the high speed rotation of the rotor blades draws the filter cake and surrounding liquid into the workhead. The high shear mixing action rapidly combines the materials.

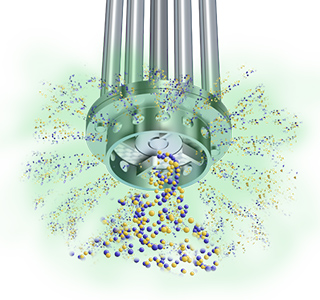

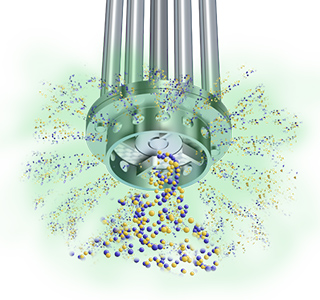

Stage 2

The liquid and solid ingredients are driven to the periphery of the workhead by centrifugal force. The filter cake is broken down in the gap between the rotor and stator wall before being forced out through the stator into the body of the mix. Fresh material is simultaneously drawn into the workhead.

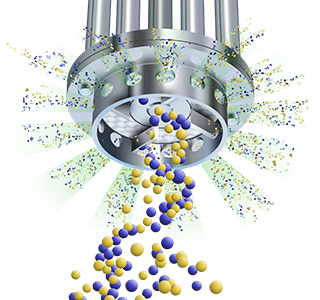

Stage 3

This creates a vigorous circulatory pattern within the vessel, ensuring all the material passes through the workhead many hundreds of times. The filter cake is thoroughly dispersed into the surrounding liquid in a short mixing cycle.

-

Stage 1

Stage 1

The vessel is charged with the aqueous or organic solvent. The mixer is started and the filter cake is added. The powerful vortex created by the high speed rotation of the rotor blades draws the filter cake and surrounding liquid into the workhead. The high shear mixing action rapidly combines the materials.

-

Stage 2

Stage 2

The liquid and solid ingredients are driven to the periphery of the workhead by centrifugal force. The filter cake is broken down in the gap between the rotor and stator wall before being forced out through the stator into the body of the mix. Fresh material is simultaneously drawn into the workhead.

-

Stage 3

Stage 3

This creates a vigorous circulatory pattern within the vessel, ensuring all the material passes through the workhead many hundreds of times. The filter cake is thoroughly dispersed into the surrounding liquid in a short mixing cycle.

The Advantages

This offers a number of advantages:

- A Silverson High Shear mixer has the capacity to disintegrate both large and small lumps of cake and agglomerates.

- The high speed operation and greater efficiency leads to shorter process time, reduced wear on machinery and considerable savings in downtime and replacement of parts.

- Pre-soaking or re-working is not required, greatly reducing process time.

- The process can be carried out in a single vessel, or continuously in-line.

- May eliminate the need for additional equipment.

- “Wash” steps can be done continuously and instantly with a Silverson In-Line mixer, greatly reducing process time and eliminating the need for additional vessels and processing stages.

The batch size, formulation, type of ingredients and the viscosity of the end product dictate which machine from the Silverson product line is best suited to individual processing requirements:

High Shear Batch Mixers

- Suitable for batch sizes up to 1000 litres

- Small units available for R&D and pilot production

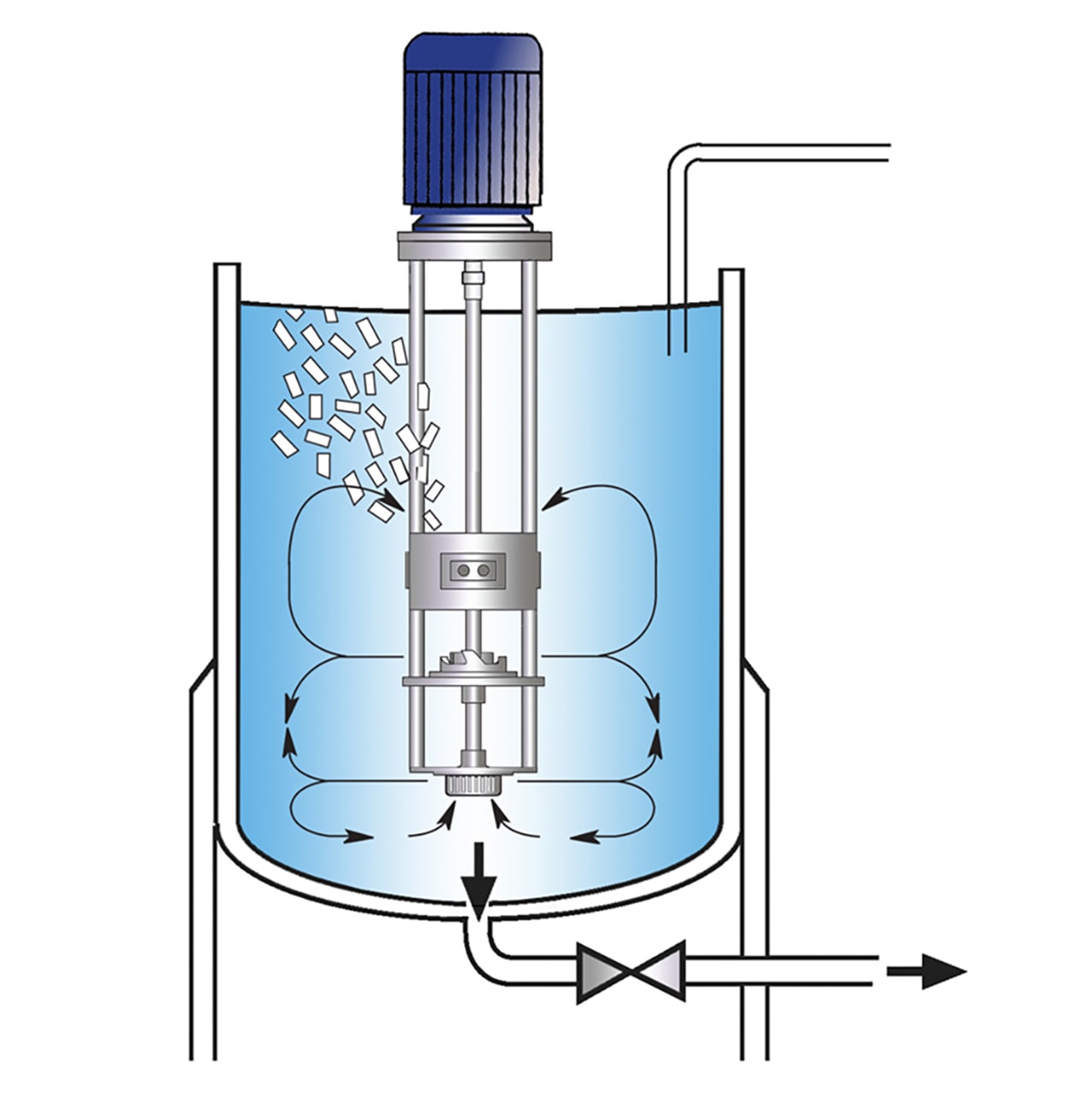

Duplex Disintegrator/Dissolver

- Twin workhead assembly

- Upper head draws materials down from surface and disintegrates large solids

- Lower head further reduces particle size and disperses agglomerates

- Suitable for higher viscosity products

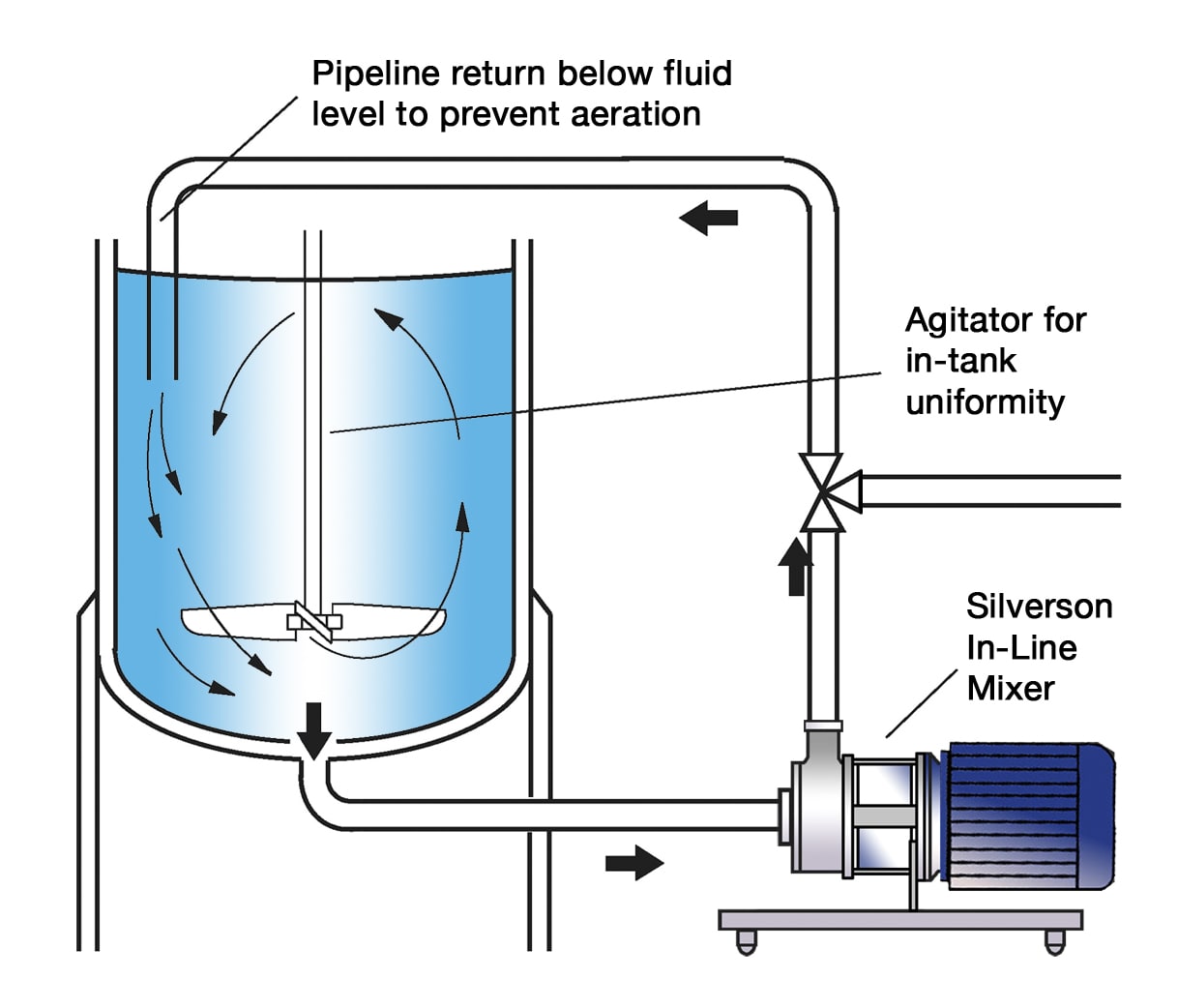

High Shear In-Line Mixers

- Ideal for larger batches

- Aeration free

- Easily retrofitted to existing plant

- Self-pumping

- Can be used to discharge vessel

- 2nd unit can be used for introducing wash fluids

- High Viscosity models available

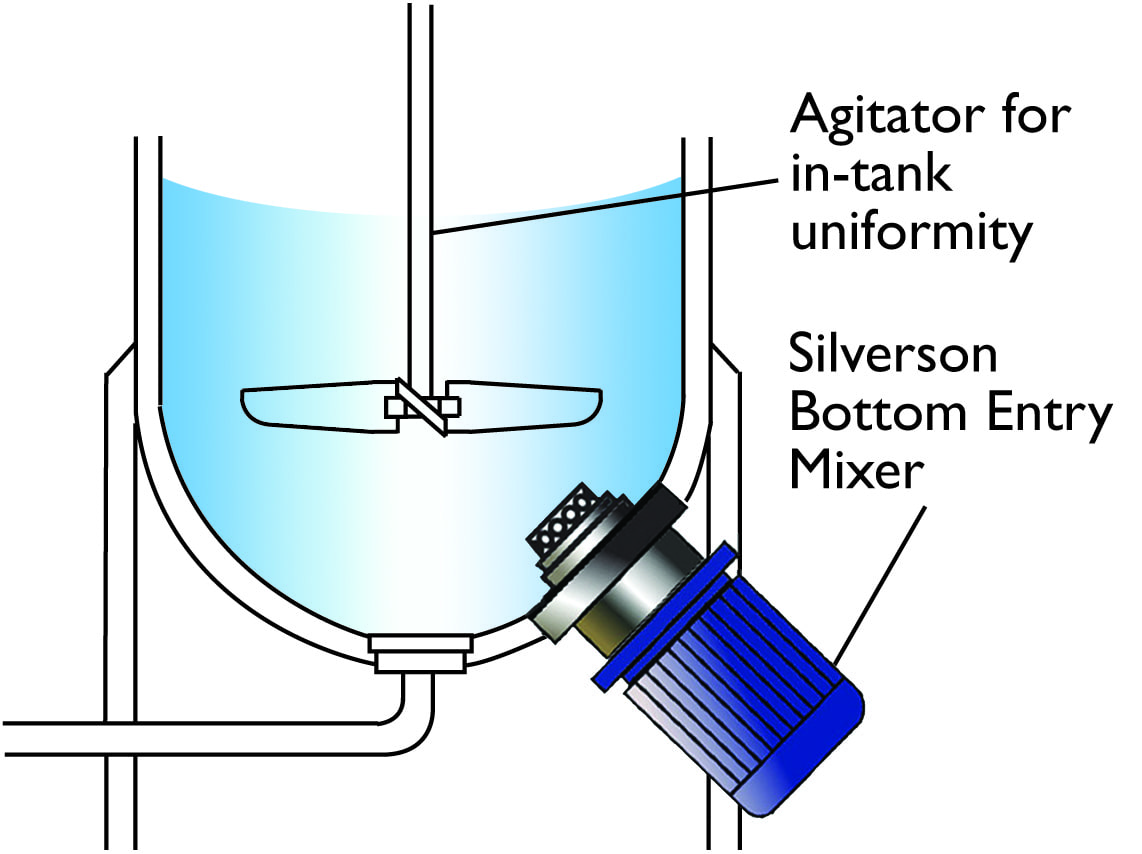

High Shear Bottom Entry Mixers

- Can be used with a Silverson Batch mixer in the vessel or an In-Line mixer in a recirculating pipeline system

- Suitable for use on higher viscosity products