High Speed Dispersion of Bentonite

Bentonite is a naturally occuring aluminium silicate clay which can take up several times its own weight of water to form a highly thixotropic colloidal suspension or gel. The gel structure is derived from hydrogen bonds which develop between the clay particles (or platelets). These bonds readily break down with shear, reforming again if the shear force is removed.

The Process

One of the principal applications for bentonite is in drilling muds, however it is widely used as a suspending and stabilising agent and as an adsorbent or clarifying agent, in many industries, some examples of which are given in the table:

Industry |

Use |

|---|---|

| Agrochemical | Anticaking agent for granular fertiliser, ingredient of pesticides, suspending agent. |

| Civil Engineering | Foundations, asphalt emulsions, grouts. |

| Cosmetic | Antiperspirants, deodorants, lipstick, creams & lotions. |

| Food/Animal Food | Binder, carrier & stabiliser in pet food. Clarifier for juice, wine, & edible oil. |

| Household | Detergent bulking agent, polishes. |

| Miscellaneous | Paper coatings, paper de-inking, inks & paints. |

| Oil | Drilling mud. |

| Pharmaceutical | Stabilising, thickening & suspending agent in creams & ointments. |

Despite the diversity of end uses and the various processing methods and equipment used, there are a number of common processing requirements which must be satisfied in order to obtain maximised “functionality”:

- Mixing equipment must be capable of rapidly incorporating and dispersing the powder into the base liquid.

- The bentonite particles must be reduced to their finest constituent parts to expose the maximum surface area to the surrounding liquid and activate the gelling effect.

- A degree of shear is required to obtain functionality.

- Vigorous in-tank movement must be maintained as the viscosity rises.

The Problem

The following problems can be encountered when using conventional agitators:

- Conventional agitators do not produce sufficient shear to reduce particle size and activate the gelling effect.

- On addition to the water, the particles tend to agglomerate. The washing action of conventional mixers cannot break these down effectively.

- Long mixing cycles are required to obtain uniform dispersion and to complete hydration.

- Additional equipment such as colloid mills may be required to obtain the required particle size.

- Once viscosity increase has started, agitation of the solution and therefore powder dispersion becomes increasingly difficult.

The Solution

The above problems can be overcome using a Silverson High Shear mixer. Operation is as follows:

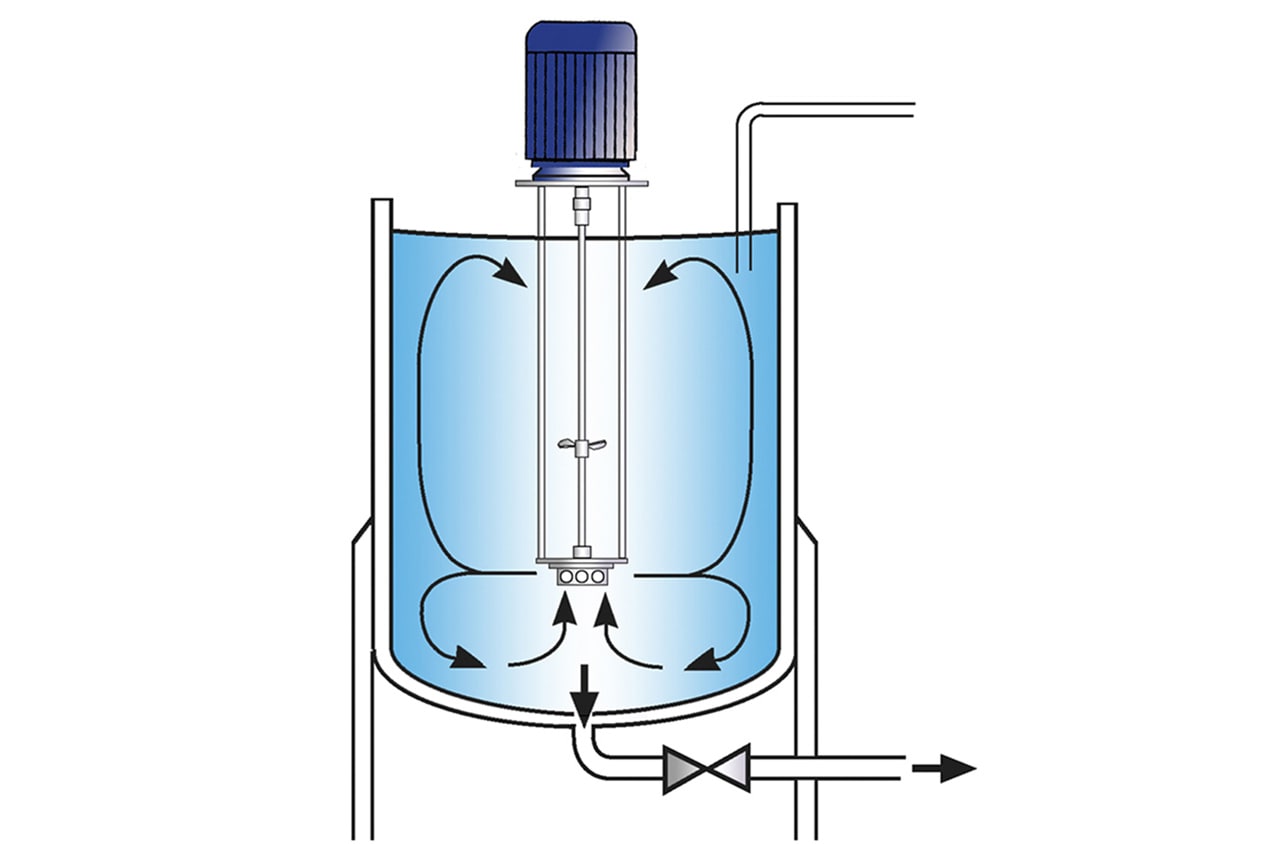

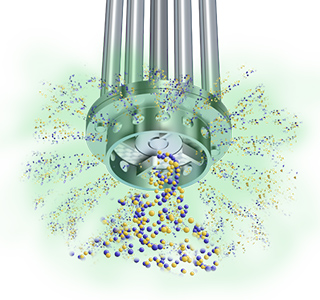

Stage 1

The vessel is charged with water and the Silverson mixer is started, creating vigorous in-tank agitation. The bentonite is added and rapidly dispersed into the water. The high speed rotation of the rotor creates a powerful suction which draws the water and clay up from the base of the vessel into the workhead.

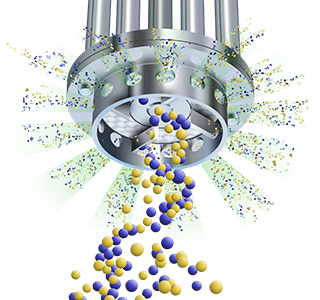

Stage 2

Centrifugal force drives the water and bentonite particles towards the periphery of the workhead. The particles are deagglomerated in the gap between the rotor and stator before being forced out through the stator and projected back into the mix at great velocity. Fresh material is simultaneously drawn into the workhead.

Stage 3

This creates a circulatory mixing pattern which ensures that the entire contents of the vessel passes through the workhead many times in a short mixing cycle, progressively breaking down the powder and exposing a greater surface area to the surrounding liquid, accelerating the hydration process.

-

Stage 1

Stage 1

The vessel is charged with water and the Silverson mixer is started, creating vigorous in-tank agitation. The bentonite is added and rapidly dispersed into the water. The high speed rotation of the rotor creates a powerful suction which draws the water and clay up from the base of the vessel into the workhead.

-

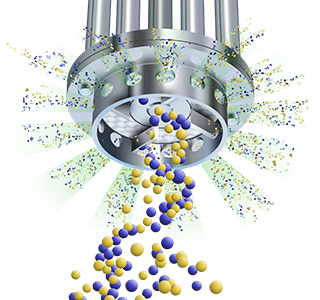

Stage 2

Stage 2

Centrifugal force drives the water and bentonite particles towards the periphery of the workhead. The particles are deagglomerated in the gap between the rotor and stator before being forced out through the stator and projected back into the mix at great velocity. Fresh material is simultaneously drawn into the workhead.

-

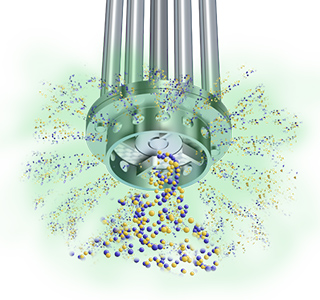

Stage 3

Stage 3

This creates a circulatory mixing pattern which ensures that the entire contents of the vessel passes through the workhead many times in a short mixing cycle, progressively breaking down the powder and exposing a greater surface area to the surrounding liquid, accelerating the hydration process.

The Advantages

This offers a number of advantages:

- Rapid dispersion of the powder.

- The intense shearing action of the rotor/stator workhead breaks down even hard agglomerates.

- It is more energy efficient and economical.

- The shorter processing time required to form a stable suspension reduces wear and therefore maintenance and spare part costs.

The batch size, formulation, type of ingredients and the viscosity of the end product dictate which machine from the Silverson product range is best suited to individual processing requirements:

High Shear Batch Mixers

- Suitable for batches up to 1000 litres

- Can be used on mobile floor stands

- Can easily be moved from vessel to vessel

- Laboratory and pilot scale units available

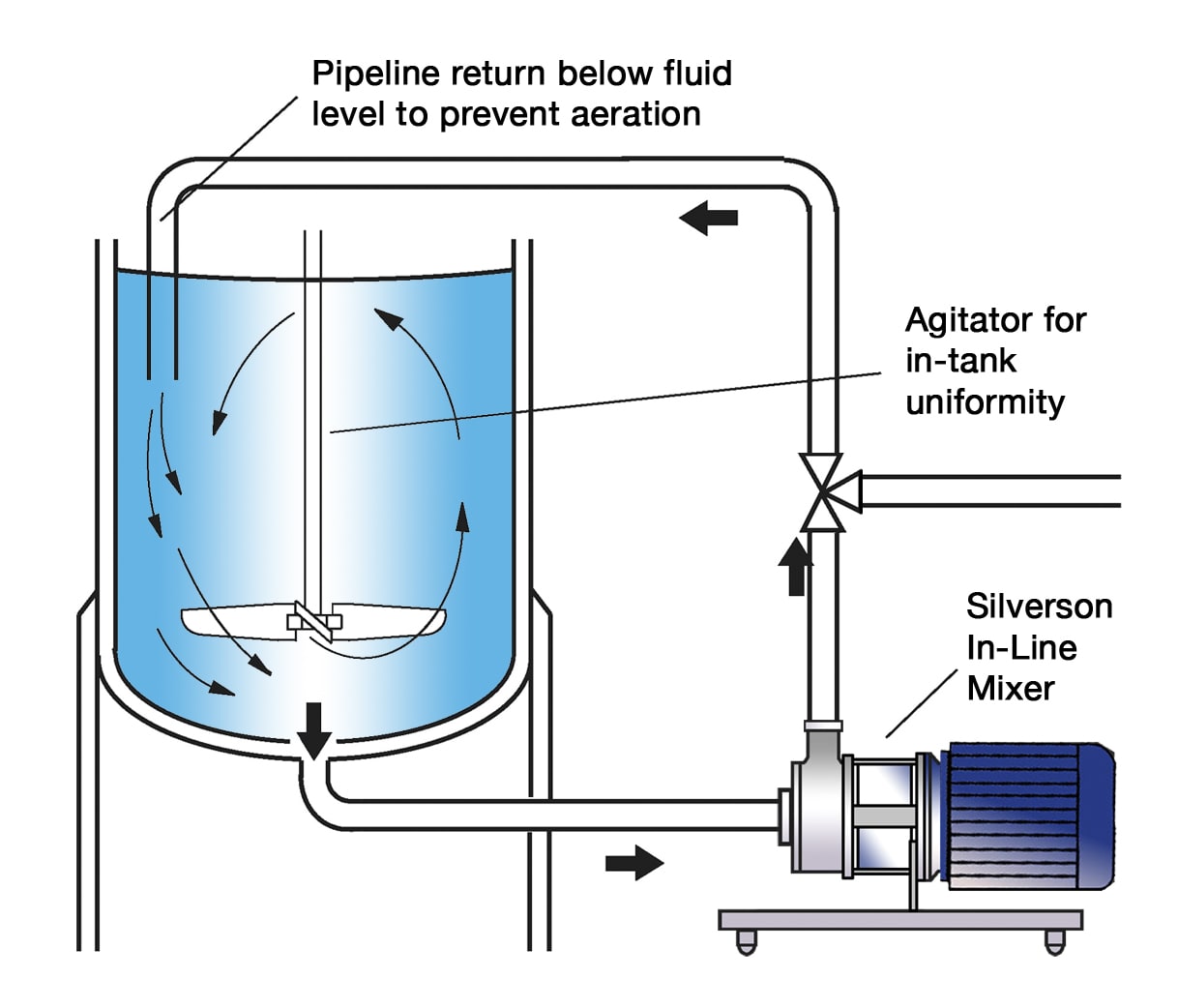

High Shear In-Line Mixers

- Ideal for larger batches

- Aeration free

- Easily retrofitted to existing plant

- Self-pumping

- Can be used to discharge vessel

- Ultra Hygienic models available

- Multistage Units available

- High Viscosity models available

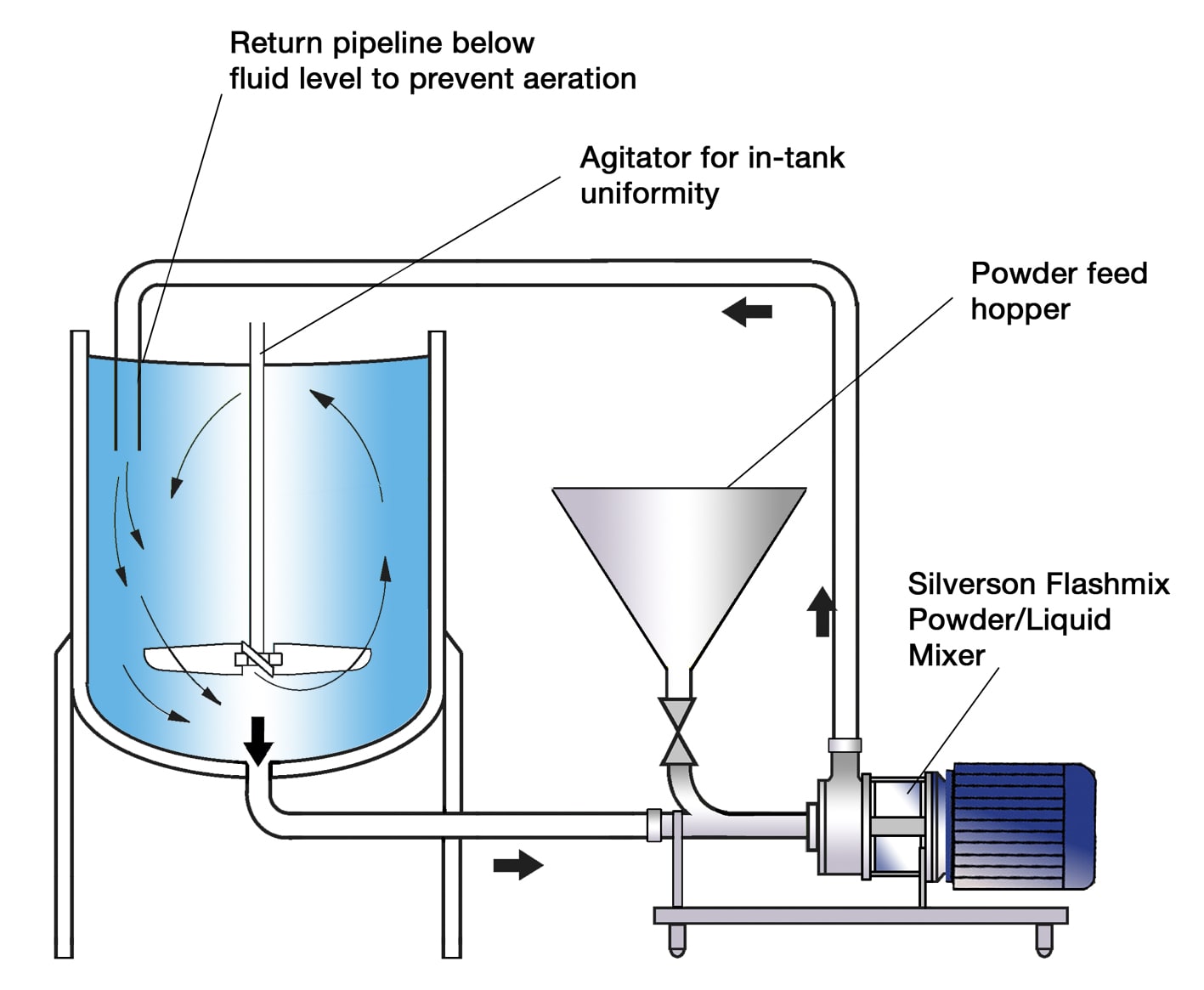

Silverson Flashmix

- Ideal for larger batches

- Capable of rapidly incorporating large volumes of powders

- Minimised aeration

- Minimised cleaning requirements

- Suitable for higher viscosity mixes

- Suitable for operation at higher temperatures

- Minimum operator input required