Ice Cream Manufacture — Hydration of Stabilisers and Emulsifiers

Stabilisers and Emulsifiers make up only a small proportion of an ice cream mix (typically no more than 1%) but contribute a number of properties to the product:

- Freeze-thaw stability. When dispersed into the liquid phase, stabilisers hydrate, binding water into a network of small droplets. The restriction in flow of “free” water in the mix prevents large ice crystals from forming during freezing.

- The thickening or gelling effect also contributes to “body” and texture (or “mouthfeel”).

- In low fat products, stabilisers act as gelling and bulking agents, replacing the body and texture normally provided by the fat content.

- Emulsifiers are added to ensure the fat content of an ice cream mix is finely dispersed to prevent the product taking on a “buttery” texture.

The Process

There are many stabilisers and emulsifiers available, (see list) and it is common to use a blend of stabilisers to obtain the optimum product characteristics. Combined stabilisers/emulsifier products are also available.

Stabilisers:

- Protein type: Gelatin, Egg white

- Gums: Guar gum, Locust bean gum, Xanthan gum

- Seaweed extracts: Sodium alginate, Propylene glycol alginate (PGA), Carrageenan

- Cellulose based: CMC, Microcrystalline cellulose (MCC)

Emulsifiers:

- Mono-diglycerides

- Polyglycerol esters

- Sorbitan esters

Preparation of a typical ice cream mix is described in a seperate report. In order to successfully disperse and hydrate the stabilisers and emulsifiers, the following process requirements must be met:

- The powder/liquid blending system must be capable of rapidly incorporating the powder and dispersing it throughout the contents of the mix.

- Stabilisers/emulsifiers tend to agglomerate when added to the base liquid. The mixer must be capable of breaking these down.

- The stabiliser/emulsifier must also be reduced to the smallest possible particle size to maximise yield. Some products are not “activated” unless particle size is sufficiently reduced.

- Similarly, a degree of shear is sometimes required to activate some products and fully hydrate them.

The Problem

A number of problems can be encountered when using conventional powder/liquid blending systems and agitators:

- Powder must be added at a controlled rate to reduce agglomerates.

- Premixing of powders, often carried out to reduce agglomeration, increases costs and process time.

- Conventional systems do not produce sufficient shear to break agglomerates down.

- Long processing times are required to complete dispersion and achieve a satisfactory consistency.

- Poor dispersion can lead to clusters of partially hydrated material building up on the walls of the heat exchanger, impairing heat transfer.

- Agglomerates can also adversely affect homogeniser performance, leading to inconsistent results.

- Frequent cleaning cycles are required, resulting in increased costs from down time, cleaning chemicals and waste of expensive raw materials.

- Incomplete hydration also reduces yield of raw materials.

- Many formulations contain unnecessarily high levels of these raw materials to compensate for poor yield and wastage.

The Solution

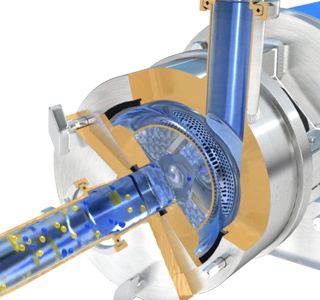

The above problems can be overcome by adding a Silverson High Shear In-Line mixer to the existing process. Operation is described below:

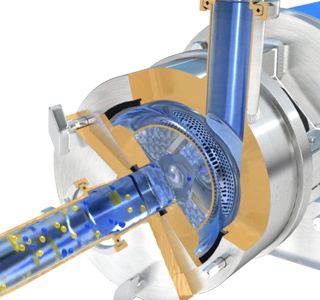

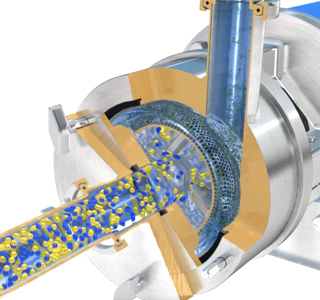

Stage 1

The high speed rotation of the rotor creates a powerful suction which draws the liquid and solid/powdered ingredients into the mixing zone. These can be added without the need for premixing.

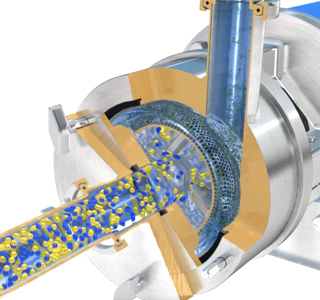

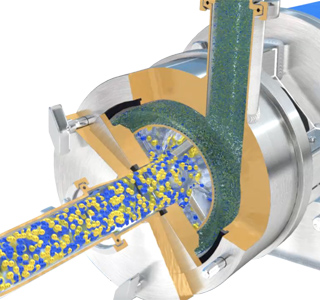

Stage 2

The materials are then subjected to intense high shear in the confined area of the workhead. Agglomerates are broken down in the gap between the rotor blade and stator wall. A lump-free mixture is rapidly obtained.

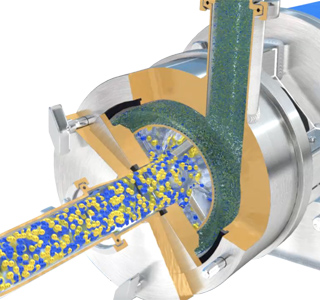

Stage 3

The product is forced out of the stator as fresh material is drawn into the workhead. A circulatory mixing cycle develops in which all the material passes through the Silverson workhead, accelerating the hydration process.

-

Stage 1

Stage 1

The high speed rotation of the rotor creates a powerful suction which draws the liquid and solid/powdered ingredients into the mixing zone. These can be added without the need for premixing.

-

Stage 2

Stage 2

The materials are then subjected to intense high shear in the confined area of the workhead. Agglomerates are broken down in the gap between the rotor blade and stator wall. A lump-free mixture is rapidly obtained.

-

Stage 3

Stage 3

The product is forced out of the stator as fresh material is drawn into the workhead. A circulatory mixing cycle develops in which all the material passes through the Silverson workhead, accelerating the hydration process.

The Advantages

- Premixing of powdered ingredients is not necessary.

- Agglomerate-free mix.

- Rapid mixing times.

- Longer run between cleaning cycles.

- Maximised yield of raw materials as thickening agents are fully hydrated and other ingredients are fully dispersed.

- Greater uniformity between batches

The batch size, formulation, type of ingredients and the viscosity of the mix dictates which machine from the Silverson product line is suited to individual processing requirements:

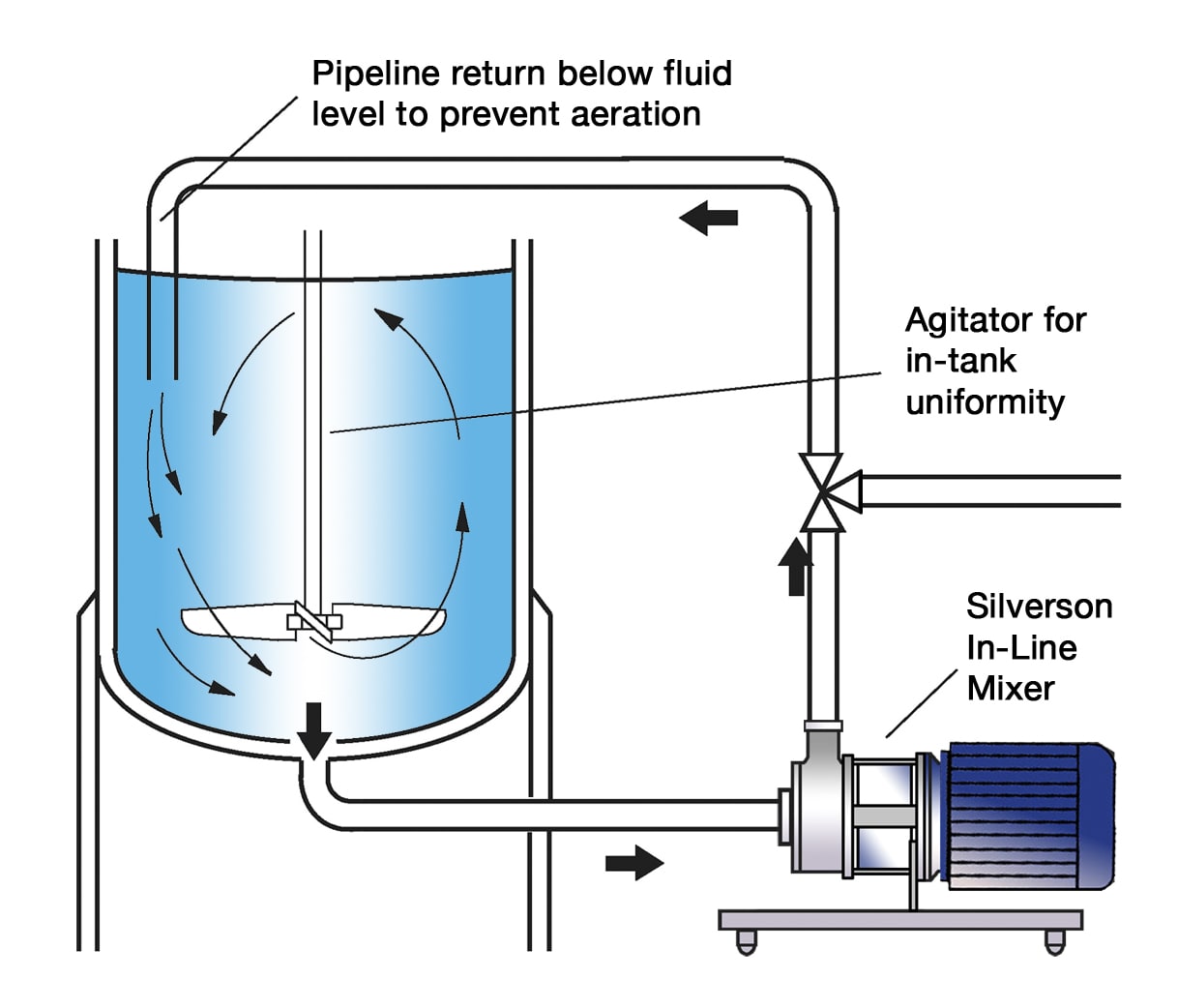

High Shear In-Line Mixers

- Easily retrofitted to existing plant

- Must be used in conjunction with an efficient in-tank agitator to wet out powder

- Aeration free

- Self-pumping

- Can be used to discharge vessel

- Ultra Hygienic models available

- High Viscosity models available

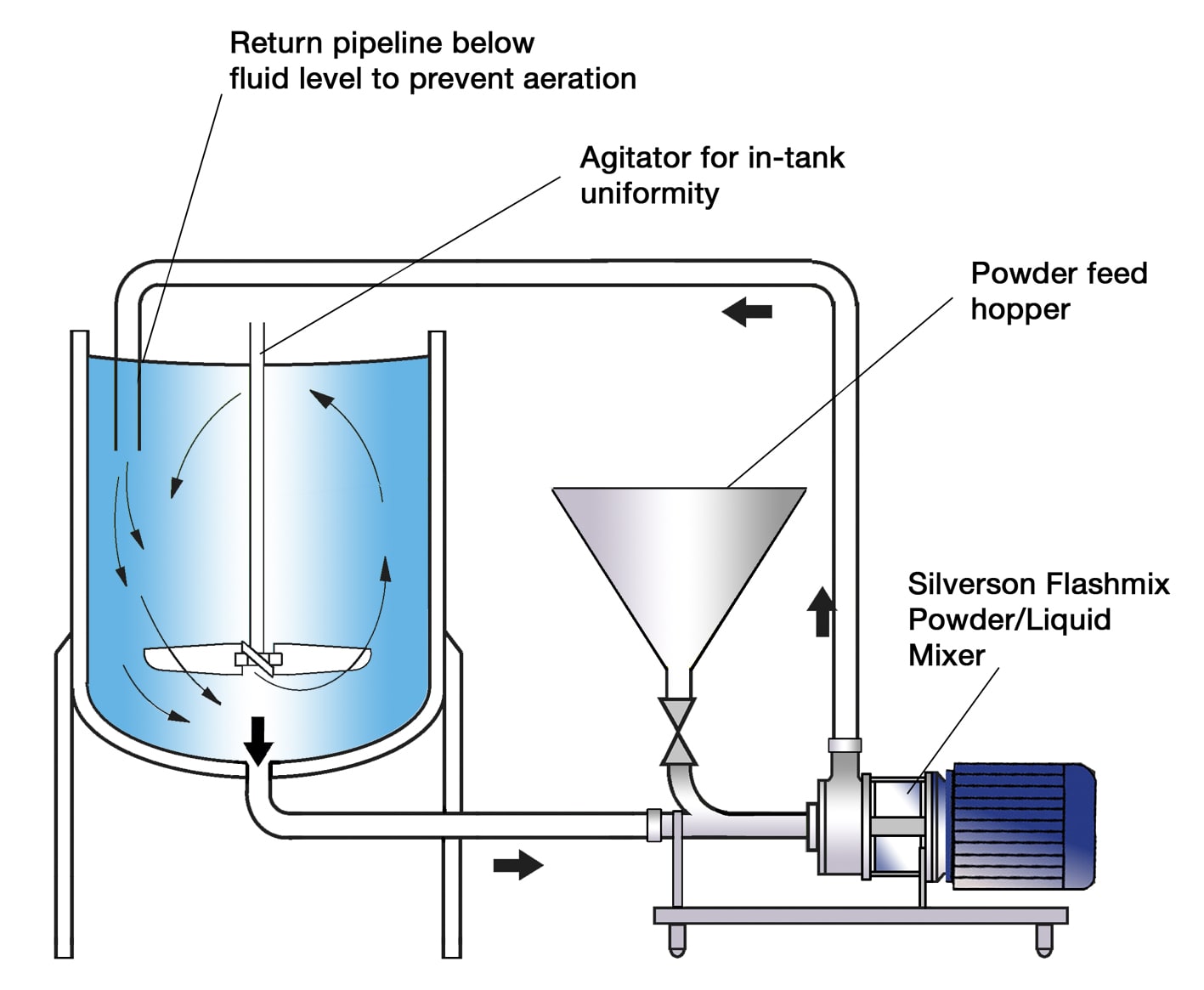

Silverson Flashmix

- Ideal for larger batches

- Capable of rapidly incorporating large volumes of powders

- Minimised aeration

- Minimised cleaning requirements

- Suitable for higher viscosity mixes

- Suitable for operation at higher temperatures

- Minimum operator input required

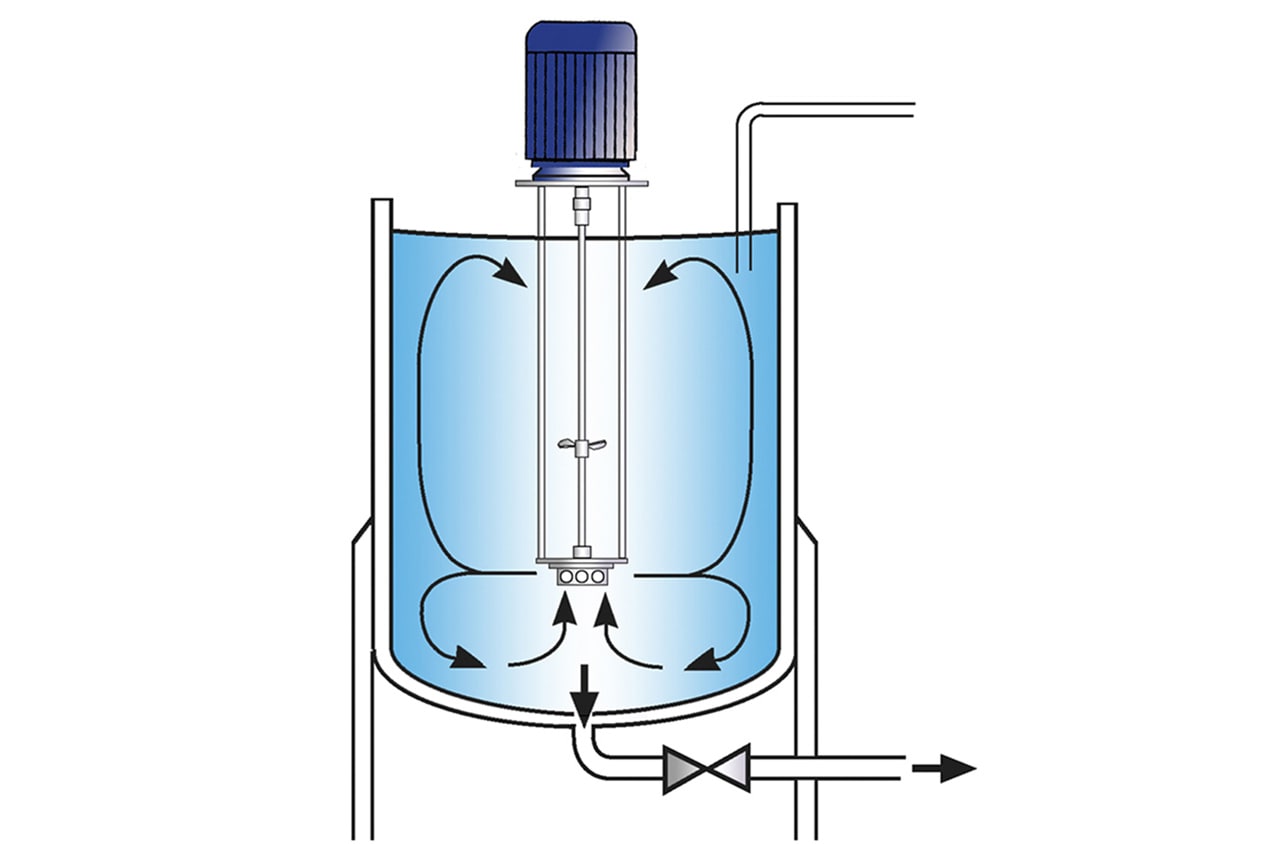

High Shear Batch Mixers

- Suitable for batches of up to 1000 litres

- Can be used on mobile floor stands

- Can easily be moved from vessel to vessel

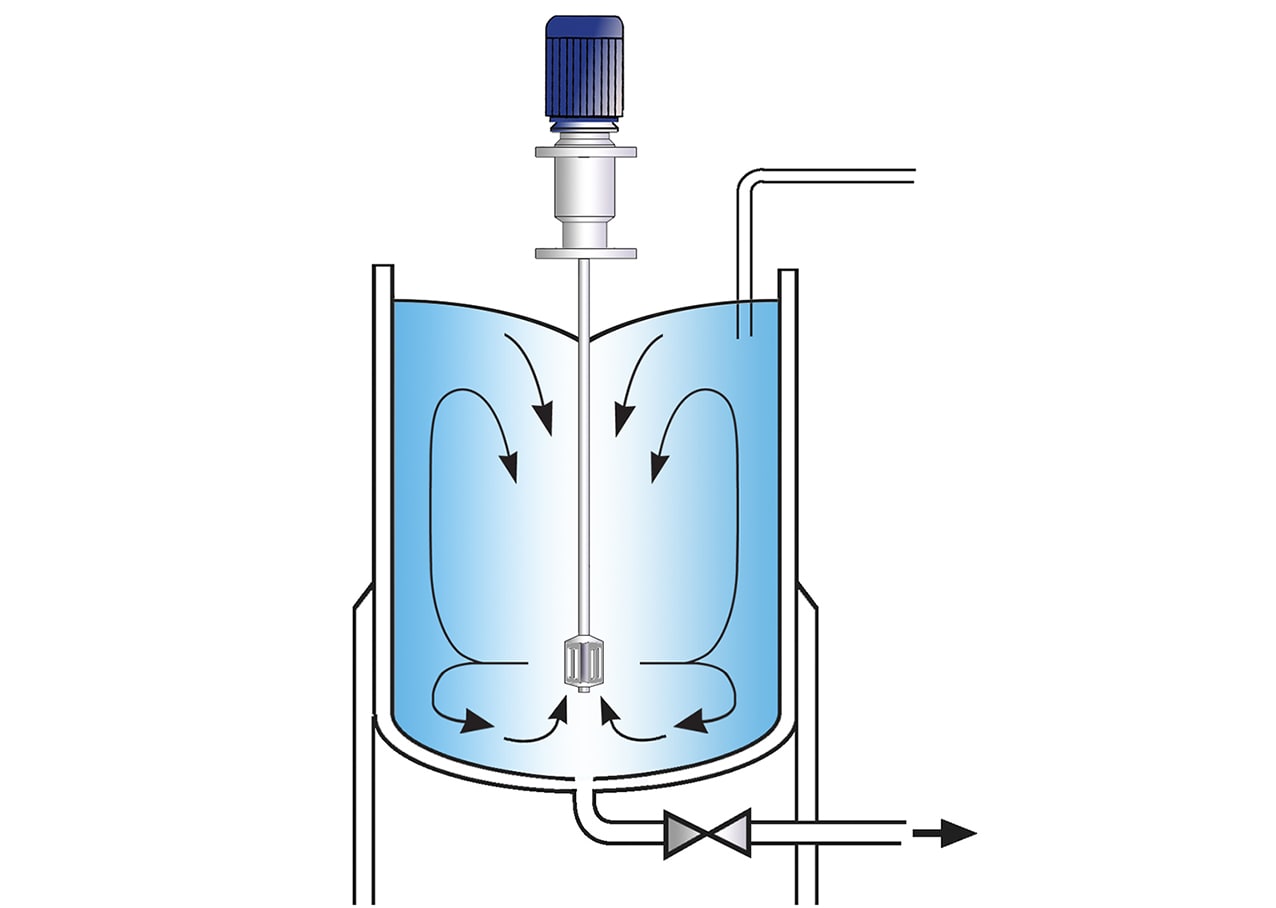

Silverson Ultramix

- Excellent in-tank movement

- Capable of rapidly incorporating large volumes of powders

- Ultra Hygienic CIP design

- Ideal for higher viscosity mixes

- Low maintenance