Dispersing Locust Bean Gum

Locust Bean Gum is a thickening and gelling agent supplied as a powder. It’s able to produce high viscosity solutions at relatively low concentrations when used in combination with other hydrocolloids.

Almost all commercially produced Locust Bean Gum is consumed by the food industry and is mainly used in ice cream, yoghurt, fruit juices, cream cheese, preserves and baby food. Locust Bean Gum is a standard ingredient in many ice creams as it slows down and reduces the size of ice crystal formation due to its ability to bind water, improving the mouthfeel of the product.

There are different grades available depending on the end user’s desired gel strength, particle size and clarity.

The Process

Processing varies according to the grade of gum being used and the nature of the end product being manufactured, but a typical process can be summarised as follows:

- Locust bean gum is often used in combination with other hydrocolloids, typically agar, xanthan and carrageenan, especially where higher viscosities are required. For example, blends of xanthan and locust bean gum will form a gel with properties that cannot be achieved with either ingredient alone.

- The gum or blend of gums is often premixed with other dry ingredients such as sugar, or non-aqueous phase ingredients such as oil to try and avoid the formation of agglomerates whilst hydrating.

- Once ready, the premix is added to liquid where it will begin to hydrate very quickly.

- Locust bean gum is soluble in hot and cold water; heating is required to develop thickening effect fully.

- As mixing continues and the Locust Bean Gum hydrates, the viscosity of the mix will continue to rise.

- Mixing continues until the gum is fully hydrated.

- A filtration stage may be required if unhydrated gum remains in the mix.

The Problem

As with many other gums, thickeners and powdered ingredients, several problems can arise during processing:

- Locust Bean Gum begins to hydrate as soon it is added to water, and if the powder is not dispersed into the water quickly enough agglomerates or “fish eyes” will form.

- Even when steps are taken to prevent the formation of agglomerates, such as premixing with other ingredients, agglomerates can easily form. This can be exacerbated by operator error. Agitators do not produce sufficient shear to rapidly break these down, leading to long mixing times and low yield.

- Many formulations contain unnecessarily high levels of gum to compensate for poor yield, increasing raw material costs.

- Premixing powders or non-aqueous phase liquid with the gum adds to process time and costs.

- Unhydrated gum can gradually hydrate during storage or subsequent processing, leading to undesired changes in product viscosity and stability.

The Solution

Using a High Shear Silverson mixer can eliminate all of these problems from your mixing process. Here’s how it works:

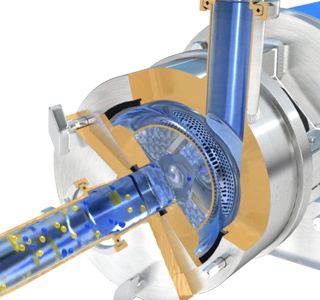

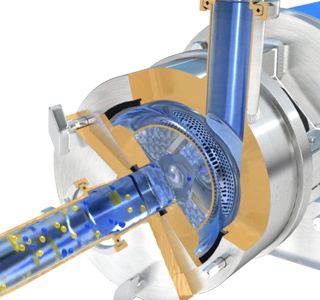

Stage 1

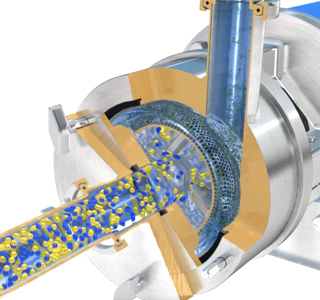

The vessel is charged with liquid and the mixer is started. The gum is added to the water as rapidly as possible. Silverson high shear mixers draws powder and liquid into the precision engineered rotor/stator workhead where they are rapidly mixed.

Stage 2

Centrifugal force drives the powder and liquid towards the periphery of the workhead, where they are subjected to intense high shear in the gap between the rotor and stator wall. The product is forced out of the stator and projected radially back into the body of the mix.

Stage 3

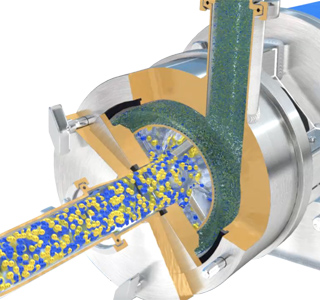

In a short time, all of the material will pass through the workhead several times, exposing an increasing surface area to the surrounding liquid rapidly completing the gum hydration. You’ll achieve an agglomerate-free, consistent solution time after time.

-

Stage 1

Stage 1

The vessel is charged with liquid and the mixer is started. The gum is added to the water as rapidly as possible. Silverson high shear mixers draws powder and liquid into the precision engineered rotor/stator workhead where they are rapidly mixed.

-

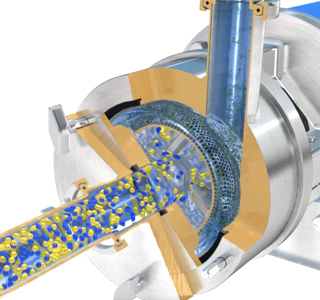

Stage 2

Stage 2

Centrifugal force drives the powder and liquid towards the periphery of the workhead, where they are subjected to intense high shear in the gap between the rotor and stator wall. The product is forced out of the stator and projected radially back into the body of the mix.

-

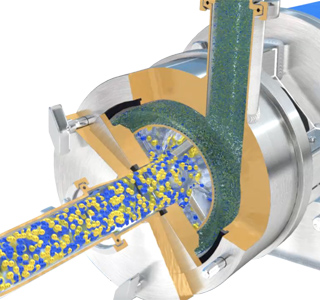

Stage 3

Stage 3

In a short time, all of the material will pass through the workhead several times, exposing an increasing surface area to the surrounding liquid rapidly completing the gum hydration. You’ll achieve an agglomerate-free, consistent solution time after time.

The Advantages

There are a number of advantages to using a high shear mixer in place of conventional mixing equipment:

- Maximised yield/functionality allows products to be formulated with reduced gum content, cutting raw material costs.

- Agglomerate-free mix.

- Rapid mixing times.

- Consistent product quality and repeatability.

- Premixing of gum with powders or non-aqueous phase is not required.

- Greater uniformity between batches.

There are several mixers in the Silverson product range capable of dispersing Locust Bean Gum. The batch size, viscosity of the end product and grade of gum used can all dictate which model would be most suitable.

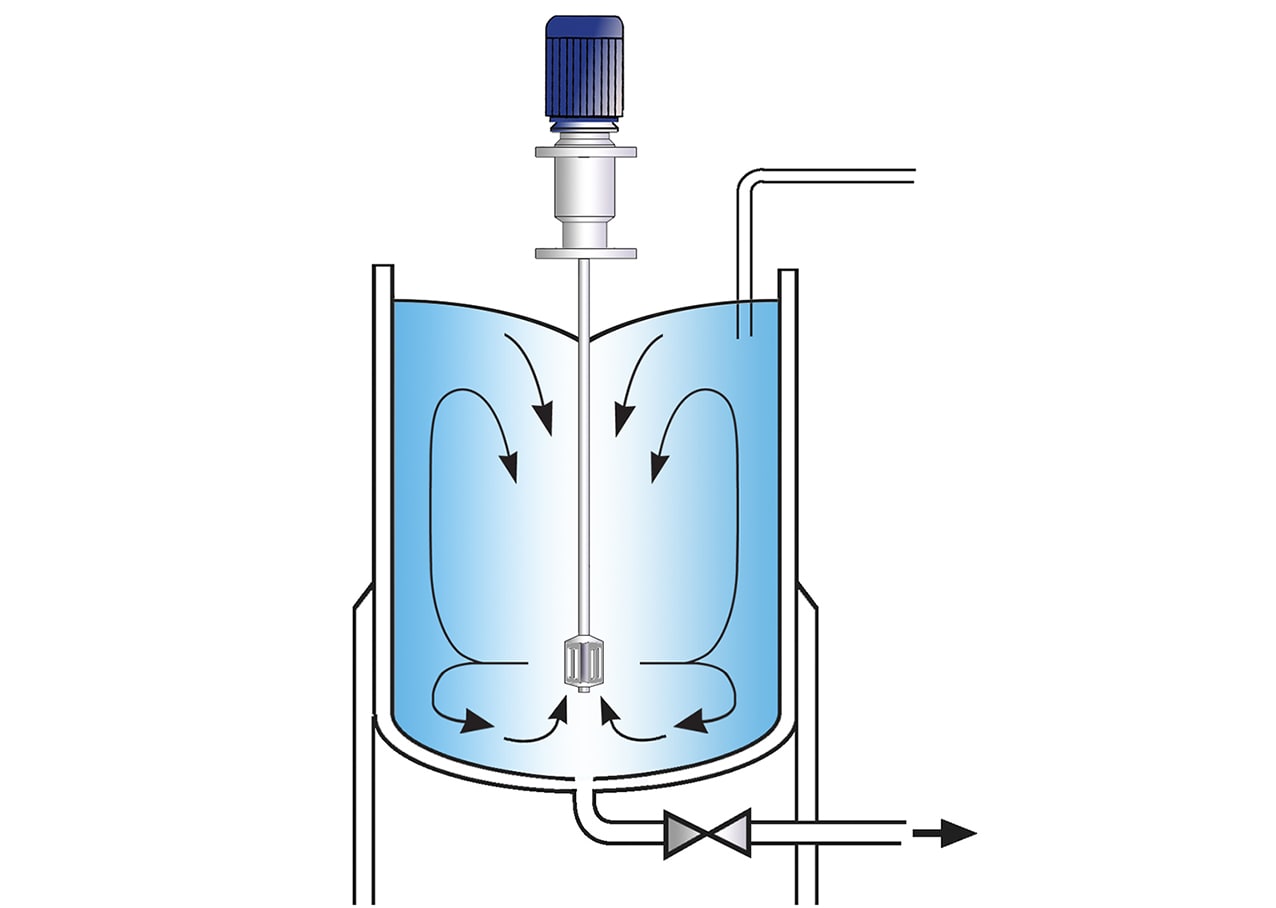

Silverson Ultramix

- Excellent in-tank movement provided by the dynamic mixing head

- Capable of rapidly incorporating large volumes of powders

- Ultra Hygienic CIP design

- Low maintenance

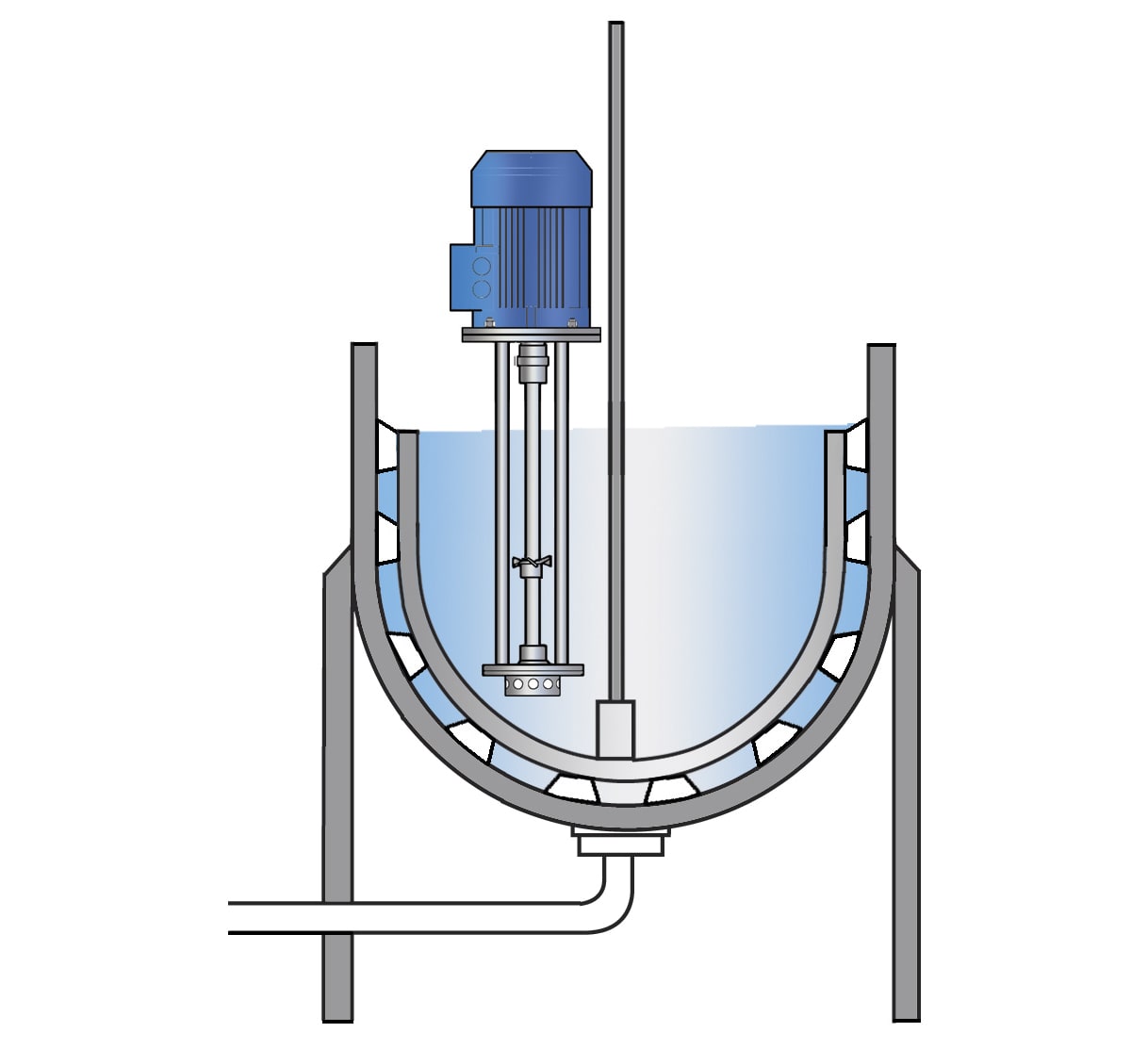

High Shear Batch Mixers

- Small units available for R&D and pilot production

- Can be used on mobile floor stands

- Can easily be moved from vessel to vessel

- Can be used alone for lower viscosity recipes or in conjunction with a scraper unit for higher viscosities (as shown)

- Easily cleaned

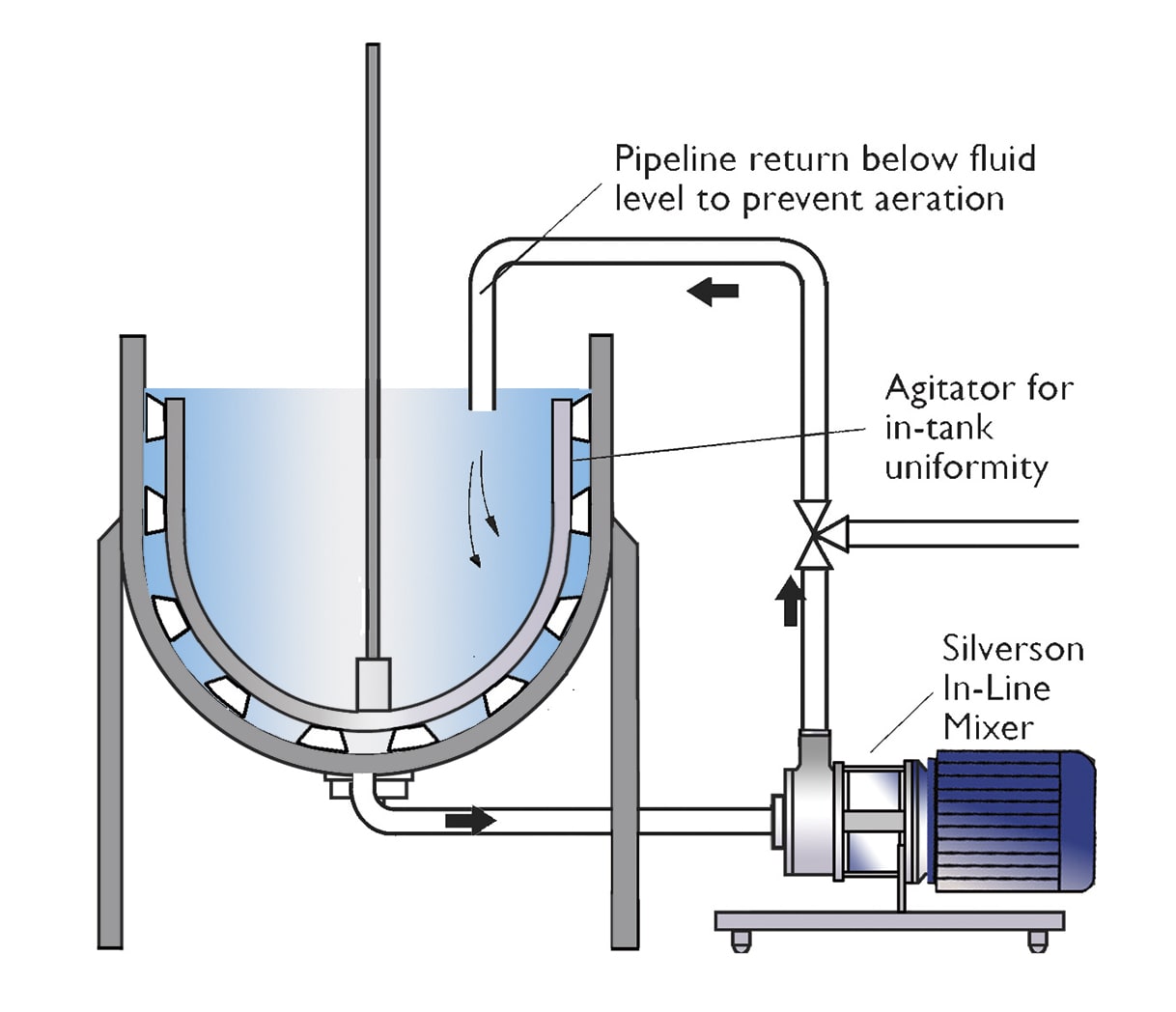

High Viscosity In-Line Mixers

- Ideal for larger batches

- Specially designed to process viscous products

- Self-pumping, no need for an additional pump even when processing higher viscosity products

- Easily retrofitted to existing process

- Minimised aeration

- Ultra Hygienic construction

- Can be used to discharge vessel

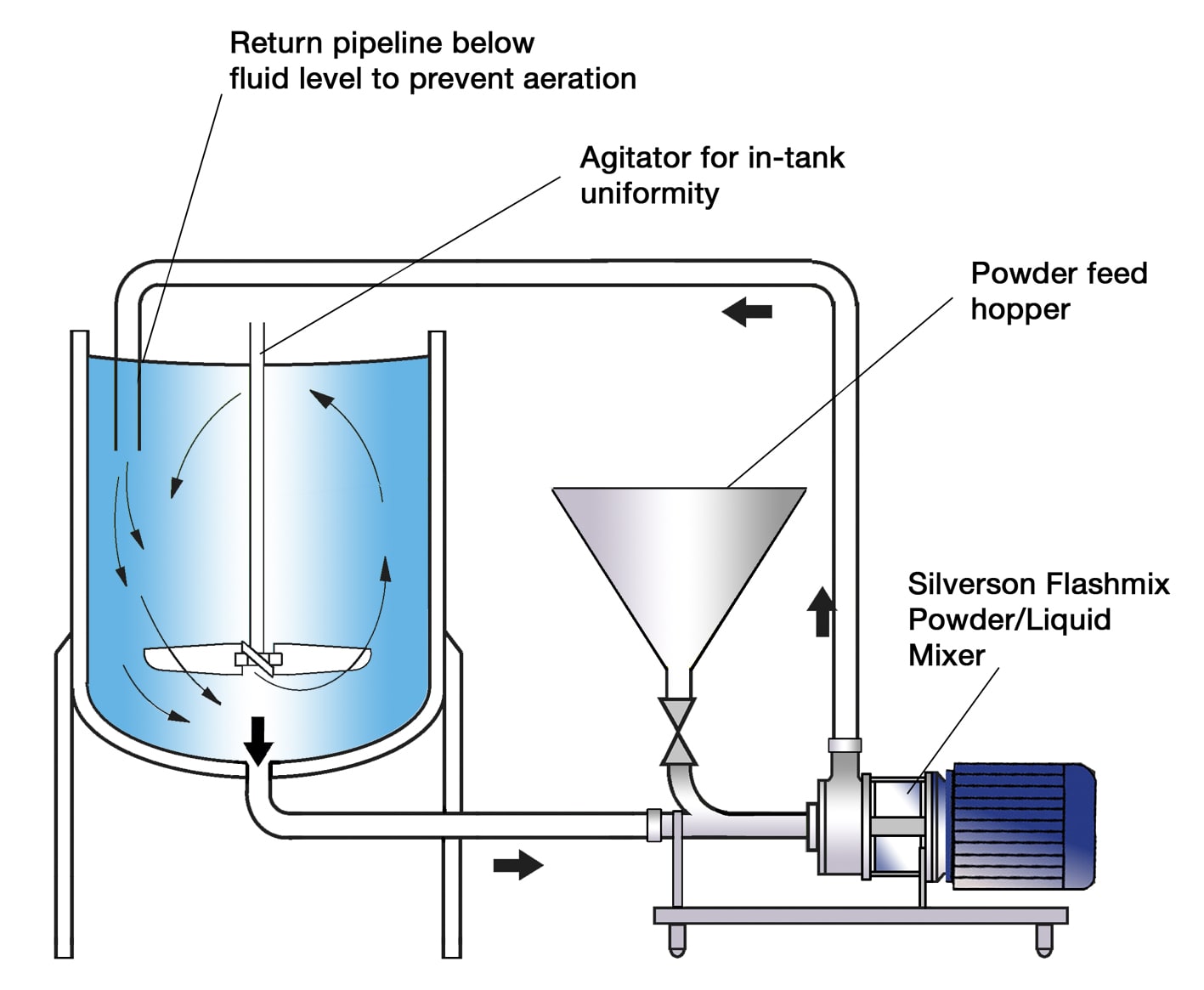

Silverson Flashmix

- Ideal for larger batches

- Capable of rapidly incorporating large volumes of powder

- Controlled powder addition rate

- Minimum operator input required

- Suitable for high viscosity mixes

- Suitable for operation at higher temperatures