Pre-Processing of Seaweed

Seaweed is used in many products, including foods and animal feeds, cosmetics, fertilisers, and a wide range of speciality chemicals. Gelling and thickening agents such as agar, carrageenan, and alginates are also derived from seaweed.

The Process

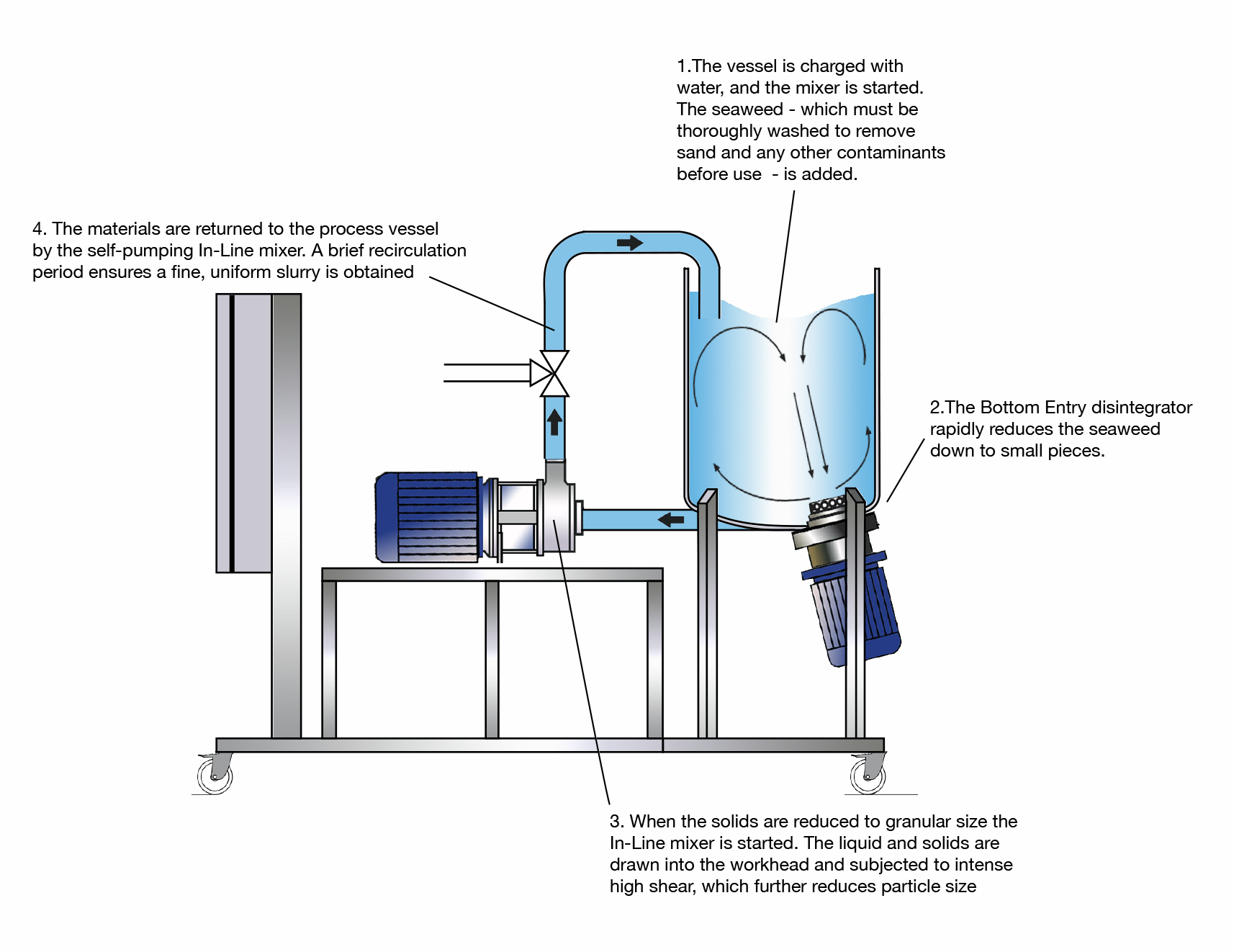

Seaweed can be cultivated in the sea or grown commercially in tanks. If it is harvested from the sea it must be thoroughly washed to remove sand and other contaminants before subsequent processing. Once harvested, seaweed is subjected to a range of different treatments and chemical processes according to the required end use. With some applications, for example where the end product is spray dried, the process may include passing through a high pressure homogeniser. Whatever the subsequent processing may be, in most cases, the process is optimised if the seaweed is rendered down to give a uniform, fine particle size. Silverson High Shear Mixers are ideal for this process.

The Solution

A Silverson Disintegrator/Dissolver can rapidly reduce seaweed to a slurry suitable for further processing according to end use. Depending on the type of seaweed being processed, a solids content of sixty percent or more can be achieved. Here’s how it works:

The Advantages

- Consistent, repeatable results.

- The unit can carry out the entire slurrying process, eliminating the need for separate chopping and blending equipment.

- Additional processing requirements such as high pressure homogenisation can be eliminated; where homogenisation is still required, the uniform premix created with a Silverson mixer will pass through the homogeniser at a much faster rate, improving productivity.

- Minimised aeration reduces degradation of the product.

- Pilot Scale plants are available for batches of up to 200 litres. Silverson also offers large scale Disintegrator Dissolver systems for bulk production. These can all be configured to suit individual process requirements; a range of optional features can be offered:

- - Special disintegrator rotor design on the Bottom Entry mixer

- - Heating/cooling jacket on the vessel and In-Line to control temperature

- - Interchangeable stators and screens on the In-Line mixer allow precise control of product consistency and particle size

In addition to the Disintegrator/Dissolver units, Silverson offers a range of standard mixers for this application, the batch size, type of seaweed being processed and nature of the end product determines which would be most suitable:

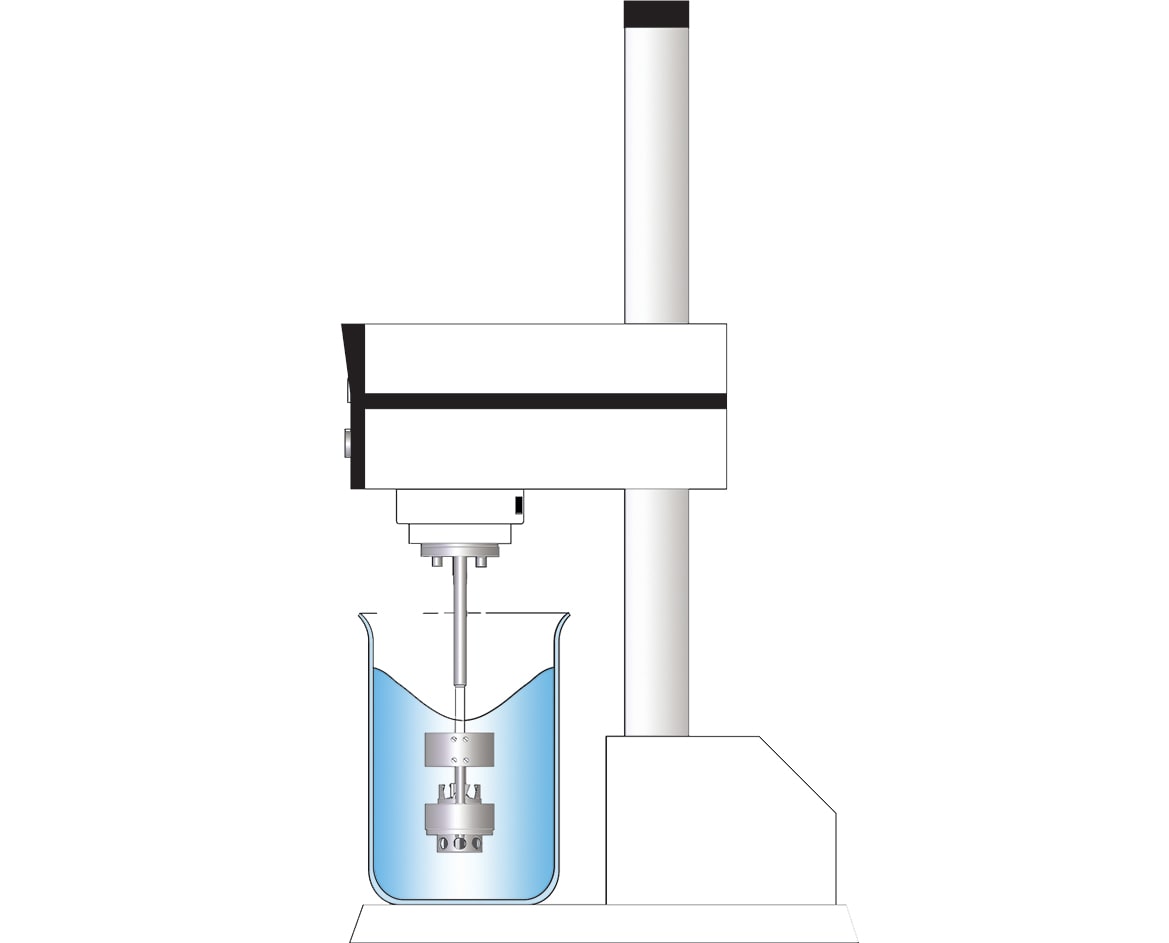

High Shear Laboratory Mixers

- Suitable for batch sizes up to 12 litres depending on viscosity

- Duplex Assembly available for disintegration of small pieces of seaweed

- Provides a means of predicting the performance of production scale Silverson mixers when scaling up

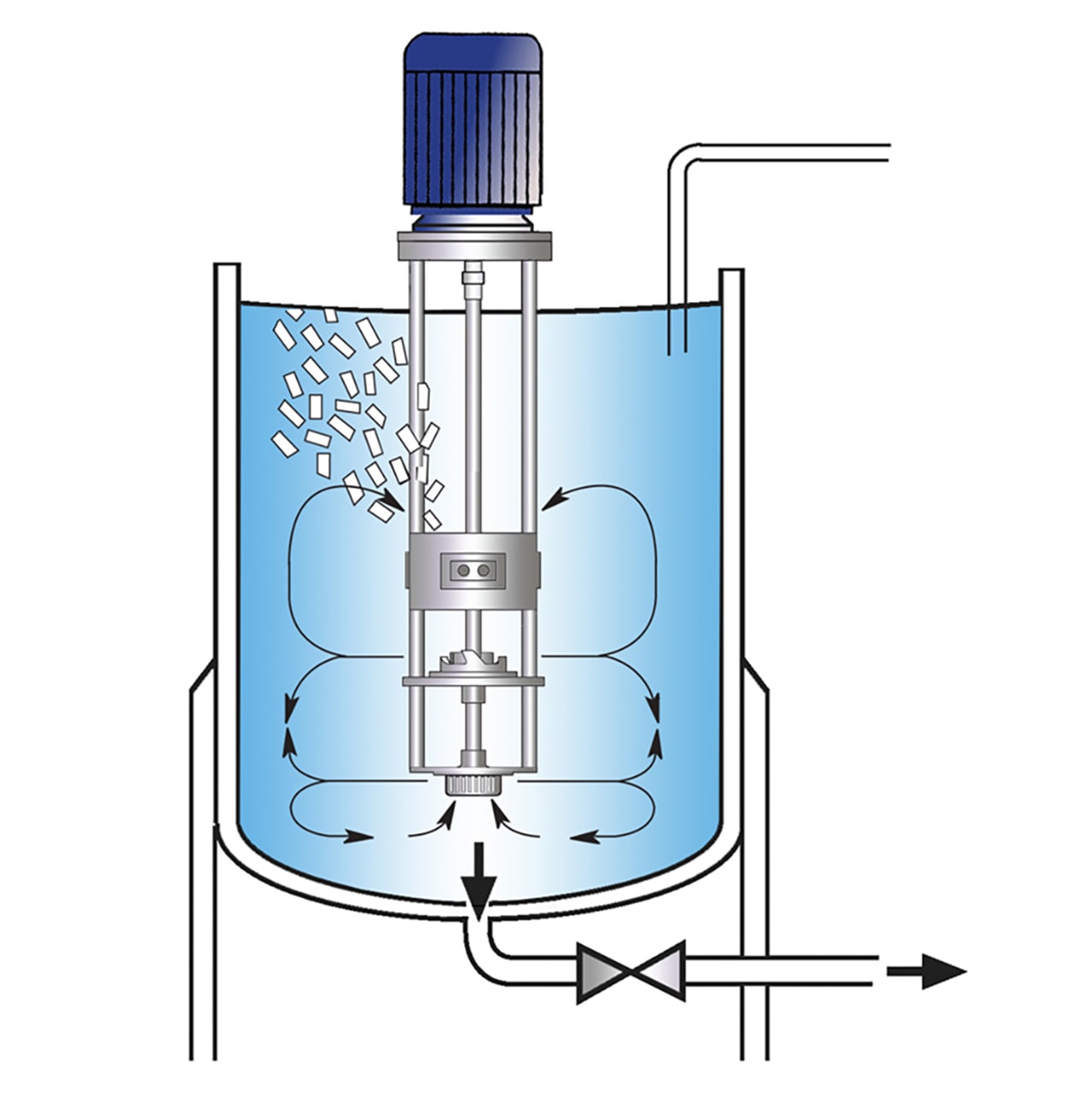

High Shear Batch Mixers

- Can be used on mobile floor stands or vessel mounted

- Duplex units (pictured) available for disintegration of larger solids

- Minimum maintenance

- Small units available for R&D and pilot production

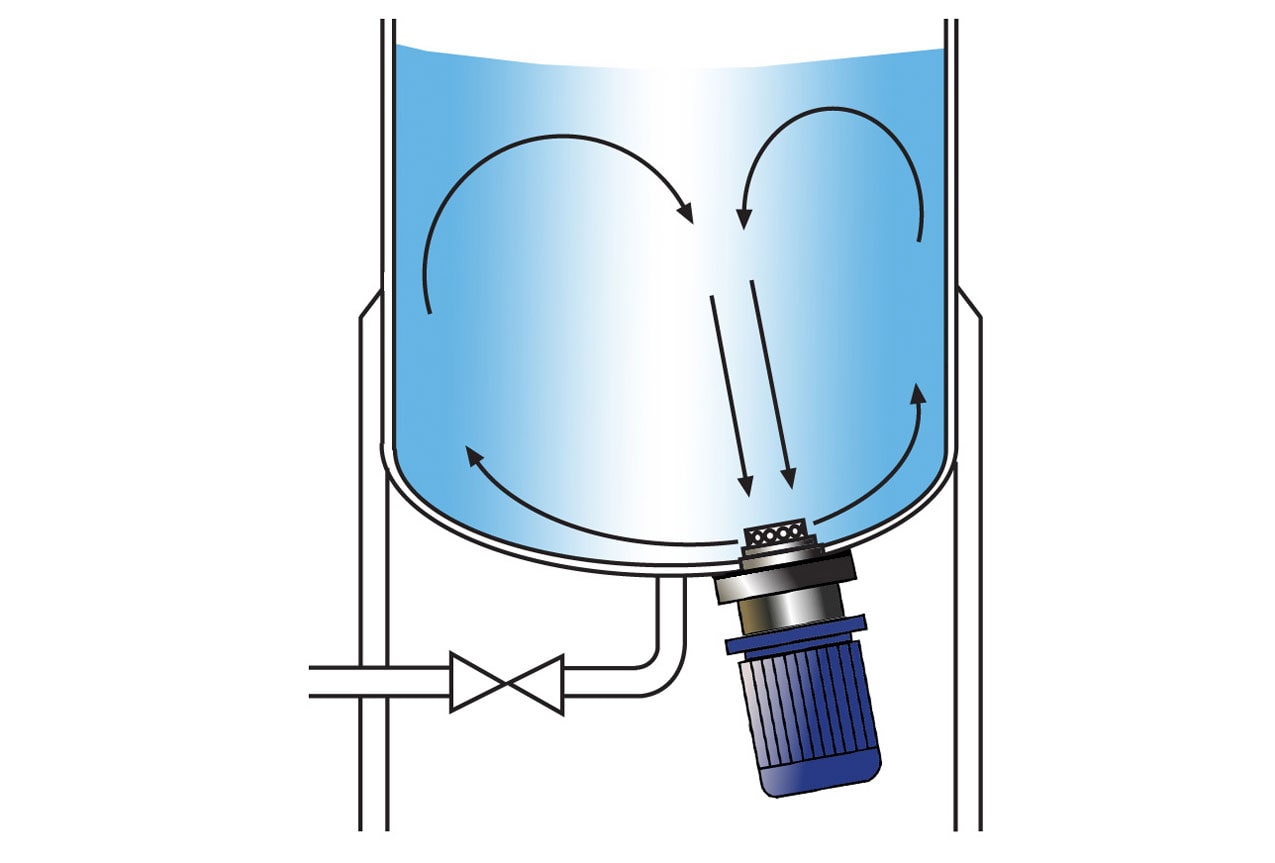

High Shear Bottom Entry Mixers

- Special disintegrator rotor design as for the Pilot Disintegrator Plant available for stand-alone Bottom Entry mixers