Scale-Up

Ramp up for production

With over 75 years’ practical experience, Silverson has the expertise and know-how to help you scale up from the laboratory or pilot plant to full production. It’s a critical stage of any process, and it is increasingly seen as a vital factor in decision-making when specifying a new mixer. The demand for ever more accurate scale-up has led to a growing emphasis on scientific research by manufacturers and academics alike.

There are theories and formulas put forward as the key to successful scale-up, but the mixing characteristics of high shear rotor/stator mixers are complex and no single rule can reliably be applied. Rotor tip speed, workhead design, power input, volume turnover, liquid rheology (characteristics of the liquid under shear) and viscosity all affect the end result. Silverson is working in partnership with some of the world’s leading academic research projects for the advancement of high shear mixing technology, and this pioneering work, combined with over 75 years’ practical experience in helping clients with some of the most difficult mixing challenges allows us to offer unrivaled expertise when it comes to scaling up.

Part of the key to our success – and that of our clients – is the accuracy with which we can predict the performance of our production scale mixers based on laboratory trials. There’s no point using a laboratory mixer capable of speeds of 25,000 rpm or more if the results cannot be replicated in production. That’s why our laboratory mixers are designed and built to the same tolerances as our production units; comparable rotor tip speed and shear rates across our entire product line means scalable results, every time.

If you want to know more about scale-up or wish to arrange a trial, contact Silverson now.

Ask The Expert

Extensive Testing Facilities

At Silverson we test our mixers under the most realistic conditions possible...yours.

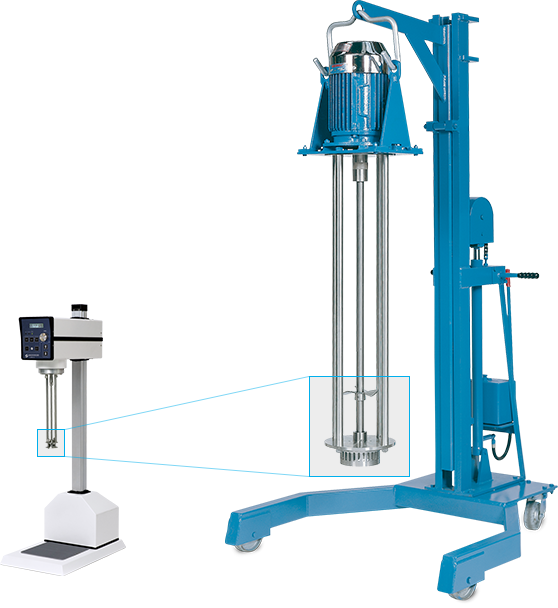

And we’re confident that they can revolutionise your process – improving product quality and consistency and dramatically cutting mixing times – so we challenge you to put us to the test. Call us and we can quickly arrange for a local Technical Representative to visit you and carry out laboratory scale trials on your product. For pilot and production scale applications our trial program allows you to conveniently test a larger mixer at your own facility.

Alternatively you can visit one of our fully equipped Test Centres. These are available for the use of all clients and allow you to discuss your application with our experienced in-house technical staff and carry out your testing program. We can replicate many typical process systems and you can test your product on a full range of Silverson high shear mixers – whether on a laboratory scale or full production volumes. We also maintain a state-of-the-art analytical laboratory, allowing immediate on-site analysis of samples during trials.

Whether you are looking to improve your existing process, or want to take advantage of the latest mixing technology in the development of a new product or process, call Silverson – we’ll find the right mixer for you.

On-Site Trials

Go ahead, take it for a spin

There’s no better way of testing a mixer than on your own product at your own facility. Silverson’s trial program allows you to test a mixer for two weeks so you can see exactly what end results you’ll get and in what times. If you want to keep the mixer for longer than the Silverson rental program allows you to keep it for as long as you need.

The trial period offers

- A mixer preconfigured to your requirements

- Expert process guidance

- A factory-trained technician to assist with installation and start-up

- Ongoing back-up and support from our technical department

Whether you want to optimise your existing process or are developing a new line, with Silverson you can be certain you get the best equipment for the job. Contact Silverson today to arrange a trial. We'll find the right mixer for you.

Customisation

Made to order

At Silverson we create mixing solutions from a truly unique perspective — yours. We understand the mixing challenges of your industry. And we know that any one mixer is not right for everyone. That’s why we will listen to your specific needs to make sure we create the right mixer for you.

We design and build every Silverson mixer ourselves. Our extensive in-house engineering and machining facilities allow us to design and manufacture mixers customised to your precise needs. Whether you require a mixer to operate under ultra hygienic conditions, high pressure or to be constructed in non-standard materials such as Hastelloy or Titanium, Silverson has the flexibility, know-how and capability to design and build a mixer to fit your exact requirements.