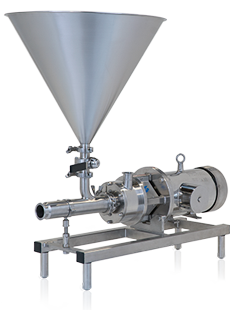

Flashmix Powder/Liquid Mixers

Flashmix Powder/Liquid Mixers

The Silverson Flashmix takes a revolutionary approach to powder/liquid mixing. Unlike many powder/liquid mixers, which use vacuum to pull in powders, the Flashmix literally forces powder into the liquid stream. This not only allows it to disperse and hydrate large volumes of powders, it means it can be used at higher temperatures and with higher viscosity mixes - offering the advantages of high shear mixing to a wide range of applications that were previously not possible.

Advantages

- Fast powder incorporation rates of up to 15,000 kgs/hour

- Agglomerate-free, consistent product, time after time

- Suitable for operation at higher temperature

- Suitable for higher concentrations of gums and thickeners

- Minimum aeration

- Hygienic - the Flashmix is based on a 3-A Certified and EHEDG Certifiable hygienic mixer

- Modular construction with a range of options to suit a wide range of applications and batch sizes

- Low power requirement; no additional pump required

- Low level, ergonomic design

- Simple - the Flashmix is easy to install, easy to operate and easy to clean

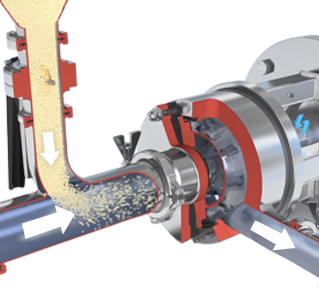

How It Works

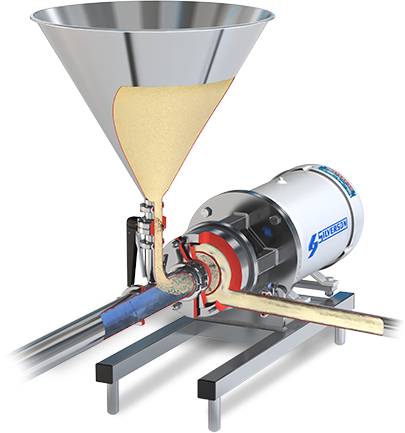

The Silverson Flashmix offers a unique method of incorporating powders into liquids, producing an agglomerate-free and homogeneous product.

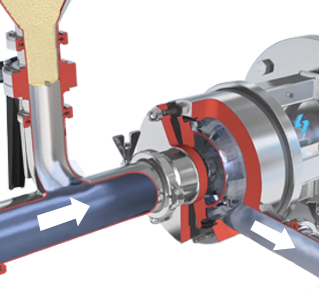

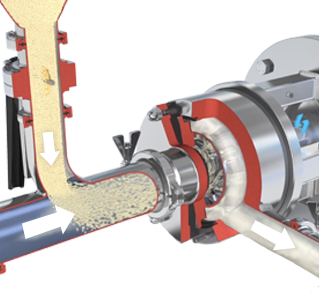

The specially modified Silverson In-Line mixer recirculates liquid from the process vessel through the Flashmix at high velocity.

The powder feed valve is opened, and the high pumping action of the In-Line mixer forces the powder into the liquid stream.

The powder and liquid components are introduced straight into the high shear zone of the mixer, and are instantaneously combined as they are subjected to intense mechanical and hydraulic shear. The resultant mix is passed back to the vessel by the self pumping Flashmix.

-

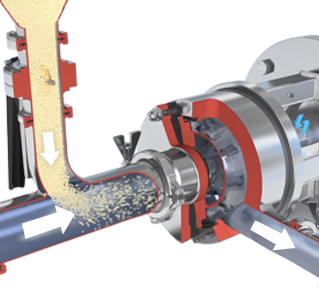

Stage 1

Stage 1

The specially modified Silverson In-Line mixer recirculates liquid from the process vessel through the Flashmix at high velocity.

-

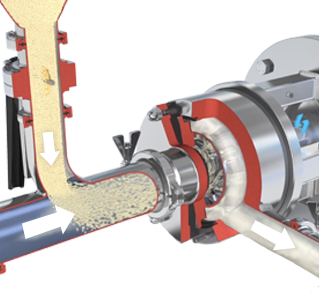

Stage 2

Stage 2

The powder feed valve is opened, and the high pumping action of the In-Line mixer forces the powder into the liquid stream.

-

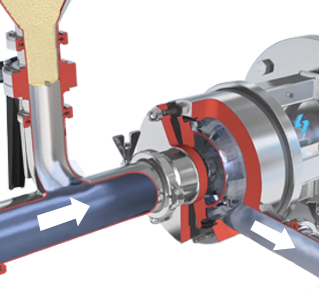

Stage 3

Stage 3

The powder and liquid components are introduced straight into the high shear zone of the mixer, and are instantaneously combined as they are subjected to intense mechanical and hydraulic shear. The resultant mix is passed back to the vessel by the self pumping Flashmix.

Videos

Flashmix – Powder/Liquid Mixer

Flashmix - How It Works

Mixer Options

Workheads

A comprehensive range of workheads and screens is available for all Silverson high shear mixers. These easily interchangeable workheads offer great versatility by allowing any machine to be adapted to perform a wide range of mixing operations including emulsifying, homogenising, disintegrating, dissolving, dispersing, blending, particle size reduction and de-agglomerating. Changing from one head or screen to another is quick and simple.

Technical Information

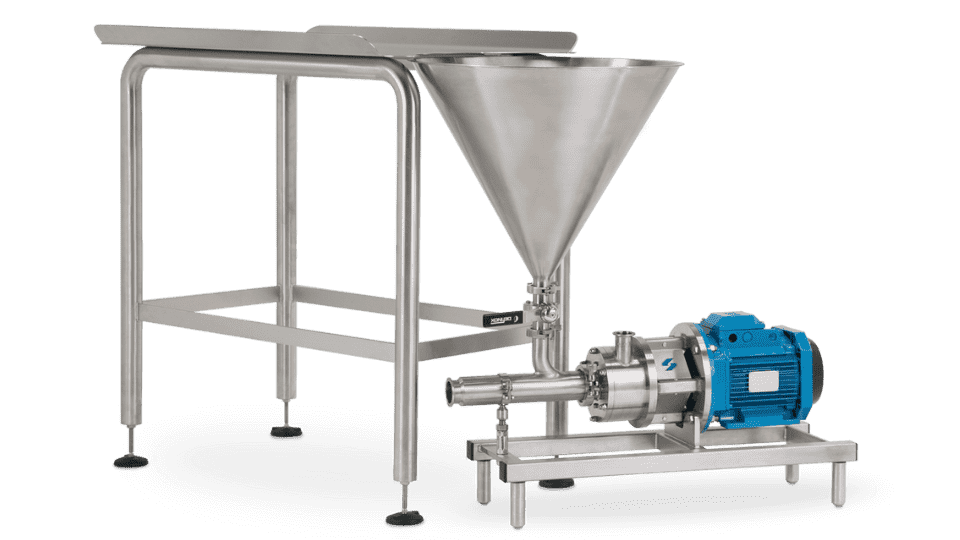

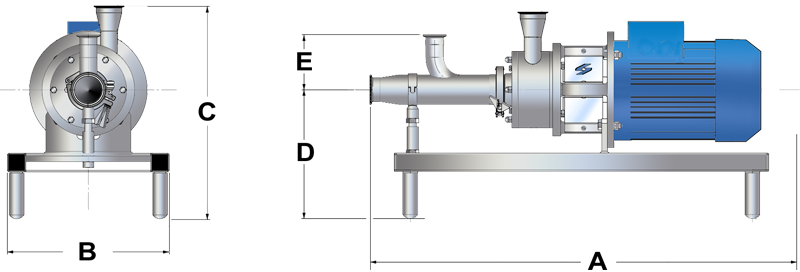

The Flashmix is a modular unit that provides a simple, effective and hygienic means of incorporating powders into liquids.

The Flashmix range comprises three production models and a laboratory scale unit, all available with a number of options to suit a wide range of applications and batch sizes.

- Materials of Construction

- All product contact parts are in 316L stainless steel. The chassis is constructed from 304 stainless steel.

- Motor Specifications

- TEFV (Totally Enclosed Fan Ventilated) motors are available as standard. Other types of motor and enclosures are available as options.

- Inlet and outlet connections

- Tri-clamp fittings are standard. Other fittings on request.

- Sealing

- Hygienic single mechanical shaft sealing is standard. Double mechanical shaft seals are available.

- Valves

- Manual butterfly valves are standard.

- Cleaning

- Designed for Cleaning-In-Place (CIP).

- Hopper

- Various hoppers are available according to model and application, including profiled hopper for minimal aeration.

- Sack Table

- A stainless steel sack table is available for FMX25 and 50.

- Automation

- As an optional extra the Flashmix can be supplied with pneumatic valves coupled to a powder sensor for semi-automatic processes.

| kW |

A |

B |

C |

D |

E |

Typical Powder Flow Rate (kgs/hour) |

Liquid Flow Rate (litres/hour) |

|

|---|---|---|---|---|---|---|---|---|

| FMX25 | 4 | 890 | 290 | 410 | 279 | 119 | 1,500 | 20,000 |

| FMX50 | 11 | 1193 | 350 | 610 | 352 | 140 | 7,000 | 40,000 |

| FMX75 | 22 | 1510 | 400 | 568 | 352 | 180 | Up to 15,000 | 90,000 |