Flashblend Powder/Liquid Mixing Systems

Flashblend Powder/Liquid Mixing Systems

Dispersing powders into liquids and creating a consistent homogeneous product, time after time, is one of the most difficult of all mixing applications. To satisfy this need Silverson has developed the Flashblend, a high shear system for rapid incorporation of a wide range of powders, including problematic gums and thickeners. The Flashblend is designed to incorporate powders on a continuous and semi-continuous basis at rates of up to 15,000 kg/hour. The system can handle a wide range of viscosities, from low viscosity products through to viscous gels.

Advantages

- Suitable for large scale production

- Agglomerate-free product

- Repeatability

- Speed

- Minimum aeration

- Improve vessel hygiene

- Viscous liquids can be incorporated into the bulk liquid via the hopper. Liquid additives can also be pumped directly into the venturi.

How It Works

The Silverson Flashblend is designed to rapidly wet out and disperse a wide range of powders into liquids. The system is based on proven technology combined with new techniques which stem from specific research into powders which are difficult to hydrate. The result is a mixer which can produce agglomerate-free homogeneous dispersion at higher production rates and concentrations than previously achievable.

The process liquid is pumped at high velocity into the venturi chamber and passes into the In-Line mixer. The combination of the pump, venturi and the pumping action of the In-Line mixer creates a vacuum in the venturi chamber.

When powder is present in the hopper, the powder feed valve can be opened. The vacuum rapidly draws the powder down into the venturi chamber where it passes with the liquid stream at high velocity into the rotor/stator assembly of the In-Line mixer.

The liquid/powder mix is then subjected to intense mechanical and hydraulic shear which ensures that it is completely dispersed and agglomerate-free. The resultant product is then passed back to the process vessel by the pumping action of the machine.

-

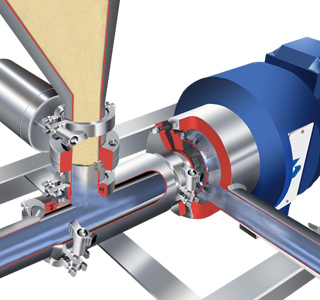

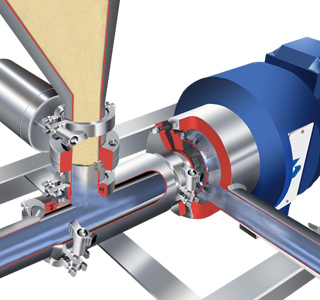

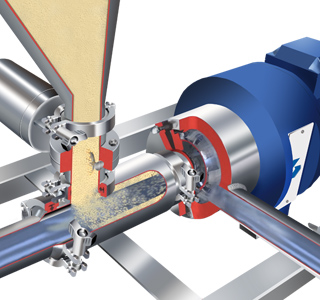

Stage 1

Stage 1

The process liquid is pumped at high velocity into the venturi chamber and passes into the In-Line mixer. The combination of the pump, venturi and the pumping action of the In-Line mixer creates a vacuum in the venturi chamber.

-

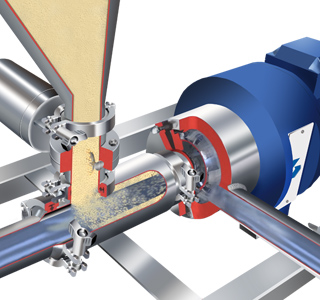

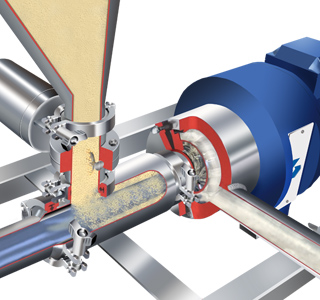

Stage 2

Stage 2

When powder is present in the hopper, the powder feed valve can be opened. The vacuum rapidly draws the powder down into the venturi chamber where it passes with the liquid stream at high velocity into the rotor/stator assembly of the In-Line mixer.

-

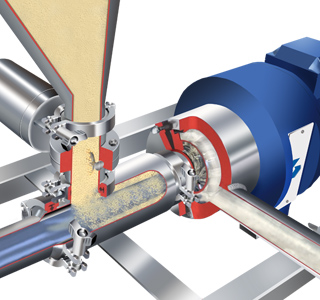

Stage 3

Stage 3

The liquid/powder mix is then subjected to intense mechanical and hydraulic shear which ensures that it is completely dispersed and agglomerate-free. The resultant product is then passed back to the process vessel by the pumping action of the machine.

Videos

Flashblend – Powder/Liquid Mixing System

Mixer Options

Workheads

A comprehensive range of workheads and screens is available for all Silverson high shear mixers. These easily interchangeable workheads offer great versatility by allowing any machine to be adapted to perform a wide range of mixing operations including emulsifying, homogenising, disintegrating, dissolving, dispersing, blending, particle size reduction and de-agglomerating. Changing from one head or screen to another is quick and simple.

Technical Information

- Capacity

- Powder incorporation rates up to 15,000 kg/hr.

- Materials of Construction

- All product contact parts are constructed in 316 stainless steel.

- Motor Specifications

- TEFV and ATEX approved Flameproof motors are available as standard. Inverter rated, stainless steel and other motors are available as optional extras.

- Connections

- Tri-clamp fittings as standard.

- Cleaning

- The Flashblend is designed to be cleaned-in-place (CIP) with sterilise-in-place (SIP) as an optional extra.

- Electrical

- Integral stainless steel control panel.

- Sealing

- Single mechanical shaft seals as standard. Double mechanical shaft seals and specialised arrangements are optional extras.

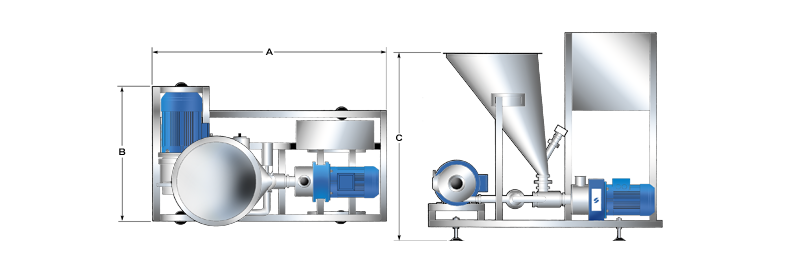

| Model |

A |

B |

C |

Total Power kW |

Maximum Powder Flow Rate (kg/hr) |

Standard Hopper Volume (litres) |

|---|---|---|---|---|---|---|

| FLB 20 | 985 | 645 | 1450 | 5.5 | 900 | 10 |

| FLB 30 | 1520 | 1000 | 1330 | 8.5 | 3000 | 100 |

| FLB 45 | 1800 | 1025 | 1850 | 18.5 | 7000 | 300 |

| FLB 60 | 2000 | 1025 | 1900 | 26 | 15,000 | 300 |

Powder flowrates are dependent on product characteristics.

The dimensions shown are approximate and certified drawings should be used for installation purposes.

All dimensions are in millimetres. Silverson reserves the right to change dimensions and specifications without notice.