Manufacture of Hummus

Hummus, or houmous is a popular dip originating in the Middle East. It is made using cooked pureed chickpeas, tahini (a paste of roasted sesame seeds), olive oil, lemon juice, garlic and spices.

The Process

Recipes vary widely according to taste and ingredients used, but the basic manufacturing process can be summarised as follows:

- Chickpeas are prepared by soaking in liquid for up to 12 hours to allow them to swell.

- They are then transferred to a kettle and cooked until soft.

- The chickpeas are typically processed by blending straight after cooking/boiling when the skins are tender and will break down more readily.

- If the chickpeas are not processed immediately, the resulting liquid thickens. (This liquid is known as aquafaba, a thickening agent that can be used as a vegan alternative to egg in other products).

- The chickpea puree is blended with tahini, olive oil and other ingredients.

The Problem

When manufacturing hummus a number of problems can arise:

- Several different pieces of process equipment may be required for the different stages of manufacturing.

- The soaking, cooking and blending process may require use of several vessels.

- Conventional cutting or grinding equipment cannot typically be used within the kettle and the product may need to be transferred through multiple process stages.

- Milling/grinding equipment can have a low throughput and can be difficult to clean as it is not typically of hygienic design.

- Separate agitators may be needed to blend in other ingredients such as tahini and spices.

The Solution

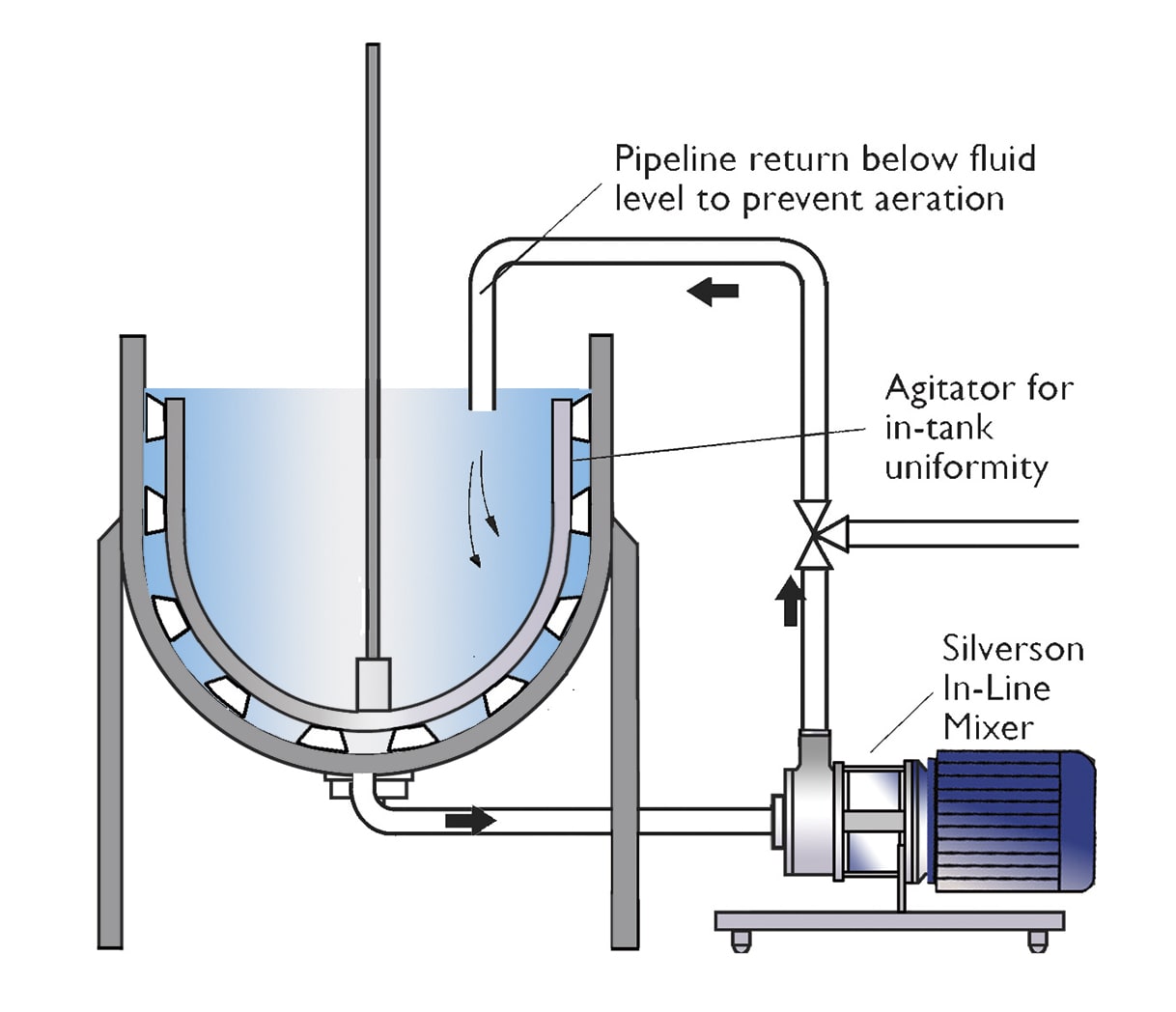

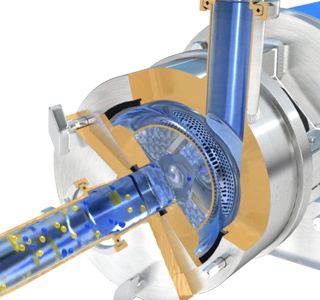

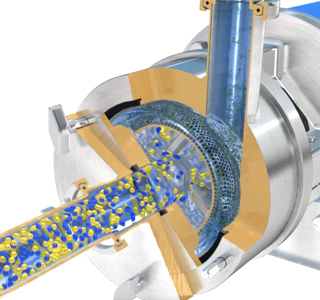

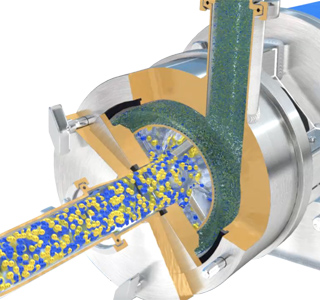

A Silverson High Viscosity In-Line mixer used in conjunction with a stirrer/scraper in the vessel is able to handle higher viscosity products such as hummus and can be used to complete the entire process. The unique “pumping rotor” design substantially increases the mixer’s capacity when compared to standard In-Line mixers. Operation is as follows:

Stage 1

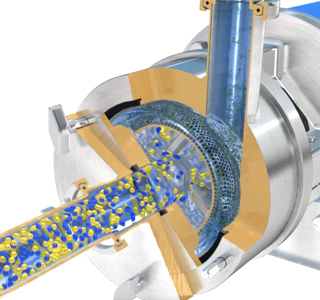

Aquafaba and pre-cooked chickpeas are added directly into the vessel without the need for pre-mixing and the mixer is started. The high speed rotation of the rotor forces the ingredients into the rotor/stator assembly where the chickpeas are instantly pureed.

Stage 2

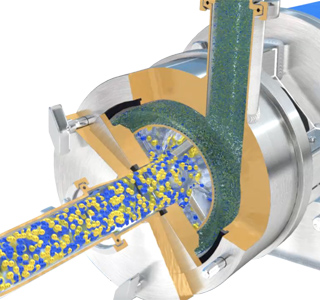

Tahini and oil are added along with garlic and lemon juice and any other spices. The ingredients are drawn into the workhead and centrifugal force drives the materials towards the periphery of the workhead where they are subjected to a milling action in the clearance between the rotor and stator.

Stage 3

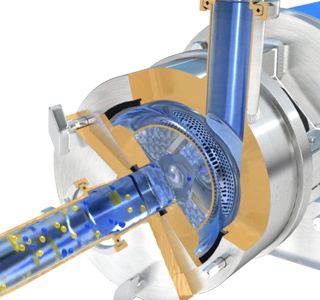

The ingredients are then forced out of the stator at high velocity, through the machine outlet and along the pipework, without the need for an additional pump. At the same time, fresh materials are continuously begin drawn into the workhead. After a brief circulation period all the ingredients are thoroughly blended together resulting in a smooth finish.

-

Stage 1

Stage 1

Aquafaba and pre-cooked chickpeas are added directly into the vessel without the need for pre-mixing and the mixer is started. The high speed rotation of the rotor forces the ingredients into the rotor/stator assembly where the chickpeas are instantly pureed.

-

Stage 2

Stage 2

Tahini and oil are added along with garlic and lemon juice and any other spices. The ingredients are drawn into the workhead and centrifugal force drives the materials towards the periphery of the workhead where they are subjected to a milling action in the clearance between the rotor and stator.

-

Stage 3

Stage 3

The ingredients are then forced out of the stator at high velocity, through the machine outlet and along the pipework, without the need for an additional pump. At the same time, fresh materials are continuously begin drawn into the workhead. After a brief circulation period all the ingredients are thoroughly blended together resulting in a smooth finish.

The Advantages

- No additional equipment is required as the In-Line mixer can be used to puree the chickpeas and blend the tahini and additional ingredients.

- The Silverson In-Line mixer can easily be retrofitted to existing tanks and cooking kettles.

- Using an In-Line mixer in conjunction with an in-tank stirrer/scraper unit avoids localised mixing, making sure the entire contents of the vessel is thoroughly mixed.

- The HV In-Line does not require an additional pump saving energy and costs on production equipment.

- Interchangeable workheads can be used to achieve the desired texture from coarser to smooth product consistencies.

Batch size, formulation, ingredients used and the viscosity of the end product dictate which machine from the Silverson product range is suited to individual process requirements. Generally, three types of Silverson mixer can be used to manufacture hummus:

Silverson High Viscosity In-Line Mixers

- Ideal for larger batches

- Easily retrofitted to existing plant

- Ultra Hygienic construction suitable for food preparation

- Self-pumping, no need for an additional pump even when processing highly viscous products

- Designed for Cleaning-In-Place (CIP)

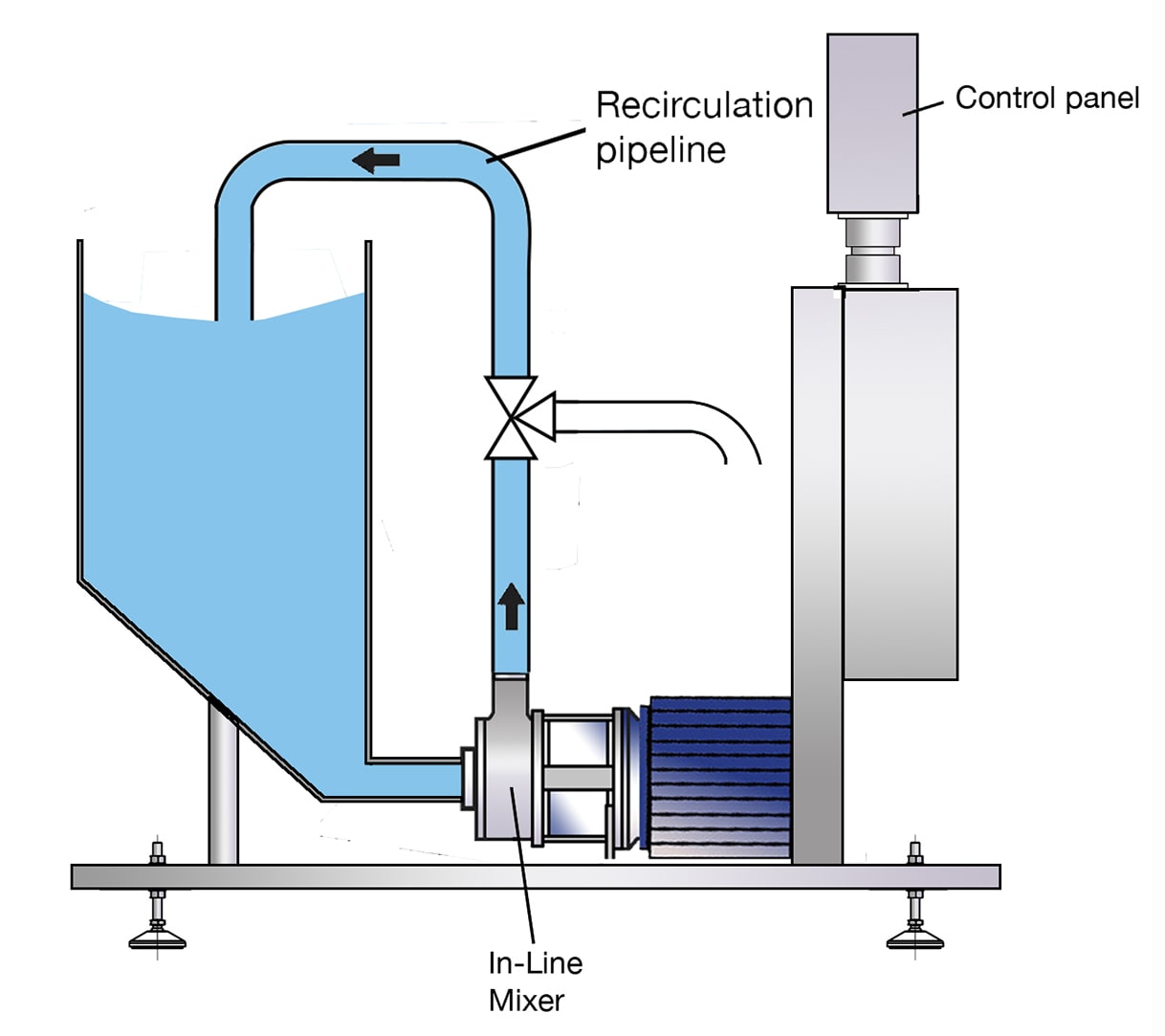

Silverson Sauce Plant

Silverson has developed a unit for the manufacture of dips and sauces for the ready-to-use market, R&D and pilot scale production:

- Ideal for smaller batches that are intended for immediate use

- Offers batch-to-batch consistency and stability

- Easily adapted to variations in product type and recipe

- Can be used for other dips and sauces including Mayonnaise

- The system is designed for handling high viscosity products without the need for additional pumps or auxiliary equipment

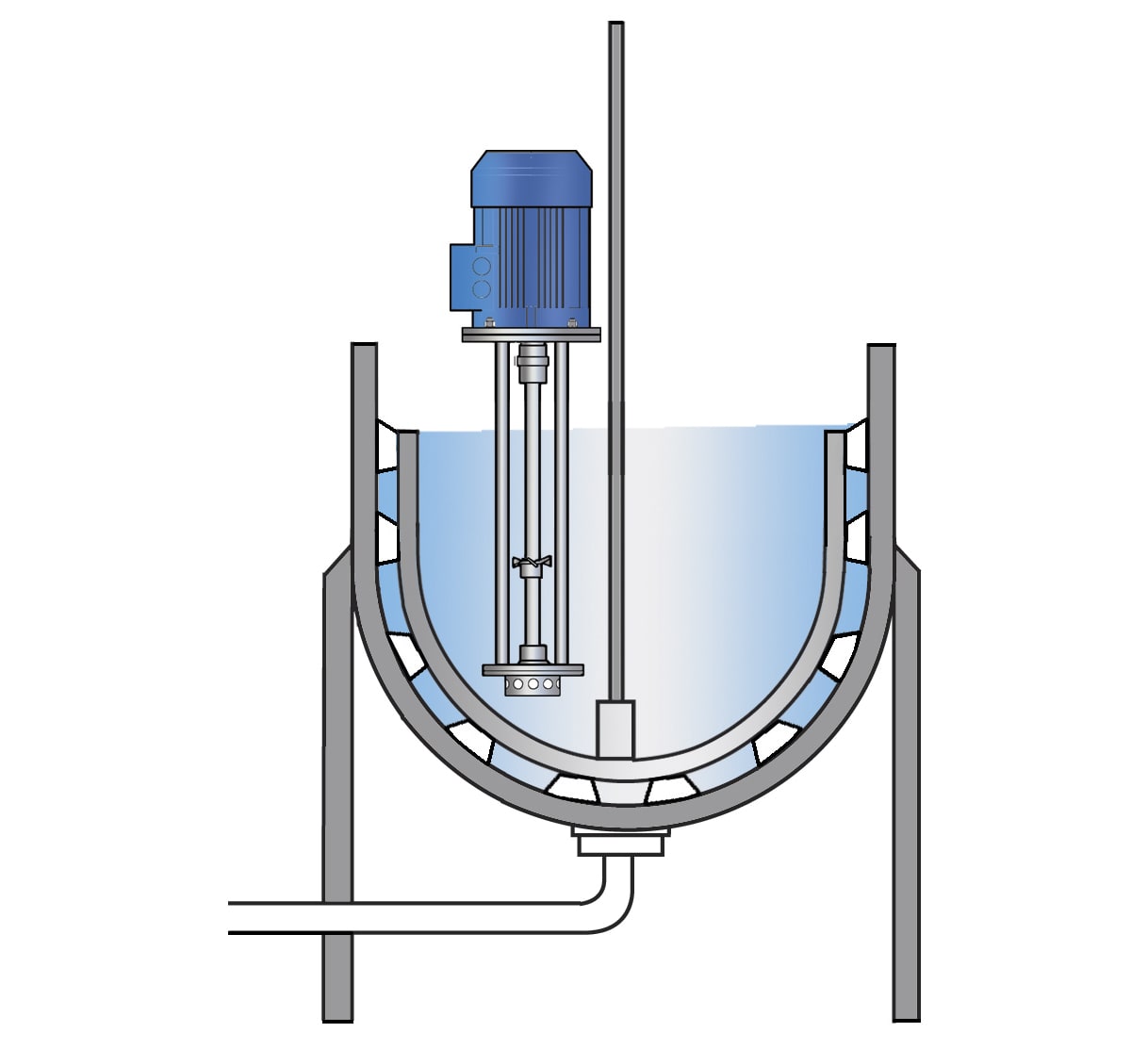

High Shear Batch Mixers

- Suitable for smaller batch sizes

- Can be used alone for lower viscosity recipes or in conjunction with a scraper unit for higher viscosities (depending on the scraper’s design)

- Interchangeable workheads for achieving different finishes