Preparation of Brines for the Meat Industry

A number of functional ingredients are added to meat to act as preservatives, flavouring, colouring, etc. These are generally dissolved into water to form a “brine” which is then injected into the meat. Another purpose of the brine is to increase the volume and weight (or yield) of the product. The increase in yield varies widely according to type, price and quality of the finished product, typically from below 15 to more than 50%.

The Process

Traditional brines consist of just water, salt and sugar; most formulations are more complex; many different ingredients are used (subject to legislation) for a number of functions as illustrated in the following table:

Ingredient |

Typical % in solution |

% in finished product |

Function |

|---|---|---|---|

| Salt (NaCI) | up to 12% | 2% | Flavouring and preservative. |

| Sugar | up to 6% | 1-2% | Sucrose/saccharose. Flavouring, also contributes to preservative effect. Other sugars e.g. dextrose, maltodextrins etc. are used to increase solids content where a high yield is desired. |

| Nitrites and nitrates | 0.5% | <0.1% | Sodium nitrite/sodium nitrate. Preservative which forms the stable pink colour of processed meats. |

| Phosphates | up to 4% | 0.5% | Used where a higher yield is required, polyphosphates increase the water binding properties of the product, allowing an increase of up to 50% and more. |

| Proteins and hydrocolloids | varies widely from 0.2% (gums) to 8% (starches) | For increased water binding for yields of up to 40-50%. Stabilisers also improve texture ("mouthfeel"). They are widely used in low-fat processed meat products. Animal proteins include whey proteins, caseinates, blood proteins, collagen, gelatine. Vegetable products include soy proteins, starches, carrageenan, locust bean gum, guar gum, xanthan gum. | |

| Antioxidants | Sodium ascorbate, sodium erythorbate. | ||

| Flavour Enhancers | Monosodium glutamate, sodium guanylate, hydrolysed meat/vegetable proteins. |

Brine solutions are normally prepared on demand. Small trolley-mounted vessels are commonly used, although larger batches are produced in bulk manufacture. Additional process requirements include:

- The mixer must be capable of completely dissolving solids such as sugar and salt to ensure they do not block the injection system and to attain their functionality.

- Similarly, stabilisers must be properly dispersed and completely hydrated to produce an agglomerate-free solution.

- The brine must be stable to prevent separation or sedimentation.

- Rectangular vessels (e.g. tote bins) are often used. Maintaining vigorous in-tank movement is essential to ensure solids do not remain undissolved or precipitate in these less than ideal mixing vessels.

- Temperatures must be kept low throughout the process. In some cases ice is added to the solution to maintain the required temperature.

- The mixing equipment must be resistant to abrasion/corrosion.

The Problem

Dissolving the salt and sugar at these relatively low concentrations is a fairly simple task which can be adequately carried out using a conventional agitator. However, several problems can be encountered:

- Formulations with higher concentrations of salt have a high S.G. This requires the input of considerable energy to fully solubilise the salt, particularly at ambient or reduced temperatures.

- Phosphates are very difficult to dissolve. Incomplete solubilisation can cause water to separate from the meat after processing.

- Stabilisers tend to form agglomerates which cannot be broken down by agitation.

- Long mixing times are required to fully hydrate and dissolve the solids. This can cause an undesired temperature rise.

- When ice is added to cool the product, it can take a long time to liquefy under agitation, reducing its cooling effect.

The Solution

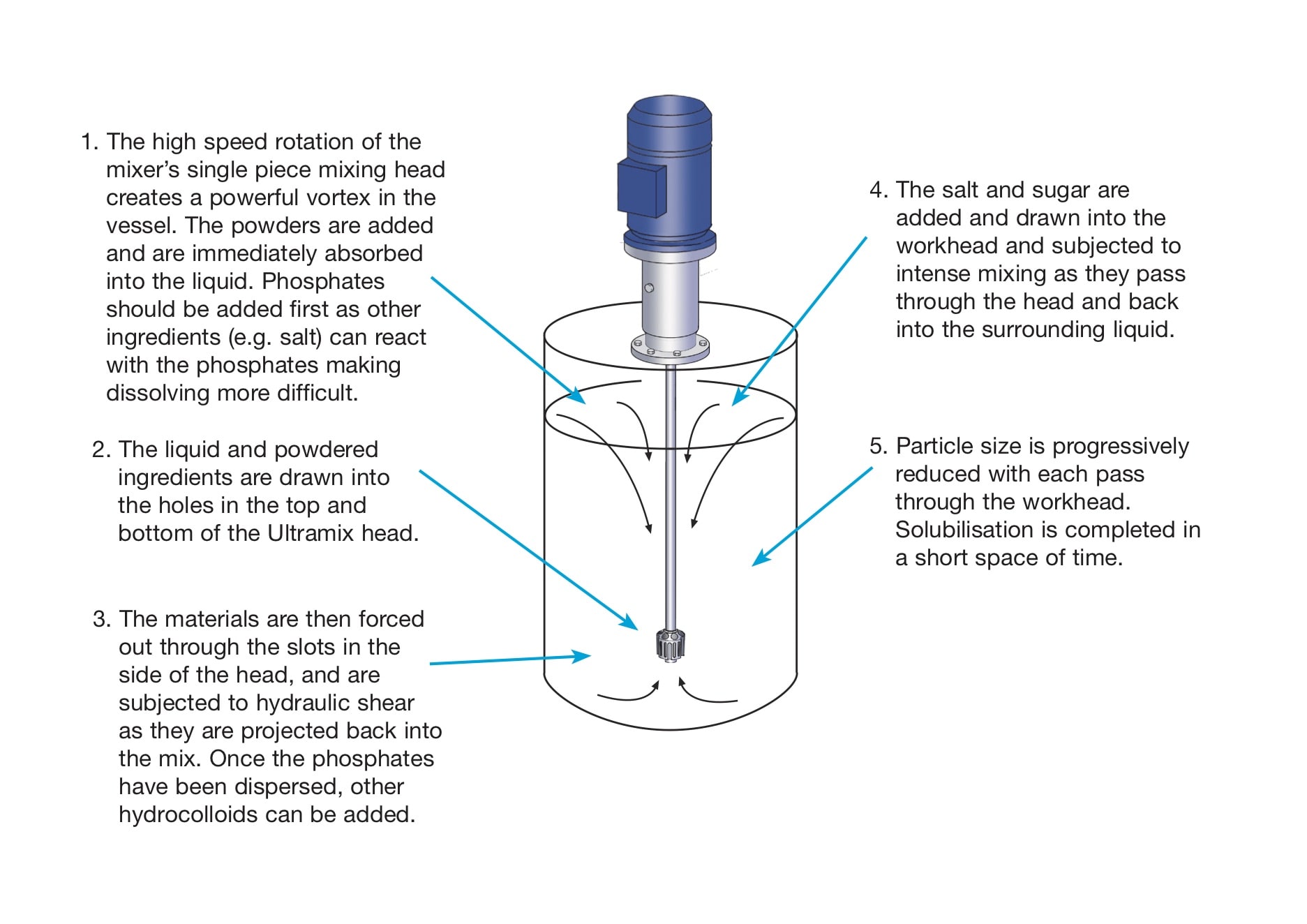

A Silverson mixer can dramatically reduce processing times and improve product quality and stability. Due to the small volumes involved, an in-tank mixer is most suitable, although In-Line machines are sometimes used for large volumes. Typically a Silverson Ultramix would be specified for brine preparation, used as follows:

The Advantages

- An agglomerate-free mix can be produced in a fraction of the time taken by conventional mixers.

- Rapid mixing time minimises temperature rise.

- Rapid powder absorption rate minimises operator error.

- Yield of stabilisers is maximised, reducing costs.

- Stable brine solution will not separate out from the finished product after injection.

- Consistent product quality and repeatability.

- Ultramix machines and Batch mixers can be used on mobile floor stands allowing them to be moved from vessel to vessel.

- Vigorous in-tank movement overcomes the difficulties associated with rectangular vessels.

- The Ultramix features a single-piece mixing head with no wearing parts or bushes. All the mixer’s product contact parts are in 316 stainless steel; cast iron or stainless steel motors should be be specified.