Preparation of Carboxymethyl cellulose (CMC) Solutions

Carboxymethyl cellulose (E466) is a hydrocolloid derived from cotton or wood pulp. It is also known as CMC, cellulose or cellulose gum.

It is water-soluble and used in the food industry, either alone, or in combination with other hydrocolloids as a thickening and stabilising agent and to bind free water. Example applications include beverages, cheese, ice cream, sauces, baked goods and frozen desserts. It can also be used to improve mouthfeel in powdered beverages. It also finds use in applications in the pharmaceutical, cosmetic and chemical industries, for example, CMC is used as a tablet binder and can be found in toothpaste and drilling muds.

The Process

CMC is available in a number of different grades. They are all soluble in water at any temperature although, as with other hydrocolloids, the powder has a tendency to form lumps or fish-eyes when in contact with water. There are a number of precautions that can be taken to prevent this; many manufacturers will offer different powder granule sizes, citing the ease of dispersing larger granules.

A typical dispersion process would be as follows:

- The vessel is agitated, allowing a vortex to form. The CMC powder would be dispersed straight into the vortex.

- Once dispersed, mixing continues to allow the powder to fully hydrate.

- CMC may be premixed with other ingredients such as sugar, to ease dispersion.

- The powder may also be predispersed into non-aqueous liquids in order to delay hydration and prevent the formation of lumps.

Case Study: Gum Solution Made 40x Faster with High Shear Mixing

The Problem

Dispersion of hydrocolloids such as CMC using conventional agitators can give rise to several problems:

- Dispersing and hydrating CMC can be a slow and difficult process, especially at higher concentrations due to its tendency to form lumps when added to water. This can be exacerbated by operator error.

- Premixing powders or non-aqueous liquids with the CMC adds to process time and costs.

- Agitators do not produce sufficient shear to rapidly break agglomerates down, leading to long mixing times and low yield. Many formulations contain unnecessarily high levels of CMC to compensate for this, increasing raw material costs.

- Filtration of agglomerates that remain in the mix considerably adds to process times and results in wastage of raw materials through filtration.

- Once viscosity increase has started, agitation of the solution and therefore powder dispersion becomes increasingly difficult.

- Long mixing times are required to complete dispersion/hydration.

- If not properly dispersed CMC will gradually hydrate during storage or subsequent processing, leading to undesired changes in product viscosity.

The Solution

A Silverson high shear mixer can dramatically speed up this process. Operation is as follows:

Stage 1

The vessel is charged with the base liquid and the mixer is started. The CMC can be added straight into the vessel without the need for premixing with other ingredients.

Stage 2

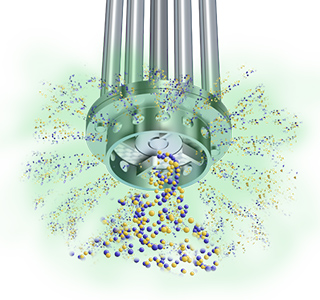

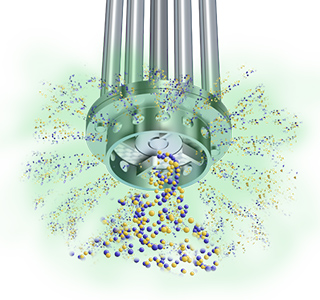

The high-speed rotation of the rotor creates a powerful suction that draws the CMC powder and liquid upwards into the workhead where it is intensively mixed in the gap between the rotor and stator, breaking down any agglomerates which may have formed.

Stage 3

The mixture is then forced out through the holes in the stator and projected back into the body of the mix, increasing the surface area of the powder exposed to liquid and accelerating the hydration process. The contents of the vessel are then recirculated back into the workhead so that in a short mixing cycle all the material passes through the workhead ensuring a fully dispersed, agglomerate-free mix is obtained.

-

Stage 1

Stage 1

The vessel is charged with the base liquid and the mixer is started. The CMC can be added straight into the vessel without the need for premixing with other ingredients.

-

Stage 2

Stage 2

The high-speed rotation of the rotor creates a powerful suction that draws the CMC powder and liquid upwards into the workhead where it is intensively mixed in the gap between the rotor and stator, breaking down any agglomerates which may have formed.

-

Stage 3

Stage 3

The mixture is then forced out through the holes in the stator and projected back into the body of the mix, increasing the surface area of the powder exposed to liquid and accelerating the hydration process. The contents of the vessel are then recirculated back into the workhead so that in a short mixing cycle all the material passes through the workhead ensuring a fully dispersed, agglomerate-free mix is obtained.

The Advantages

Silverson mixers offer a number of advantages for this application:

- Agglomerate-free mix.

- CMC can be added straight into the vessel, eliminating the operator error.

- Premixing with other powders or non-aqueous phase ingredients is not required.

- Maximised yield/functionality allows products to be formulated with reduced powder content, cutting raw material costs.

- Consistent product quality and repeatability.

- Rapid mixing times.

- Stable viscosity of end product.

- Greater uniformity between batches.

We offer mixers for a wide range of batch sizes and formulations. Consistent results can be obtained across our entire product range, allowing you to scale up easily:

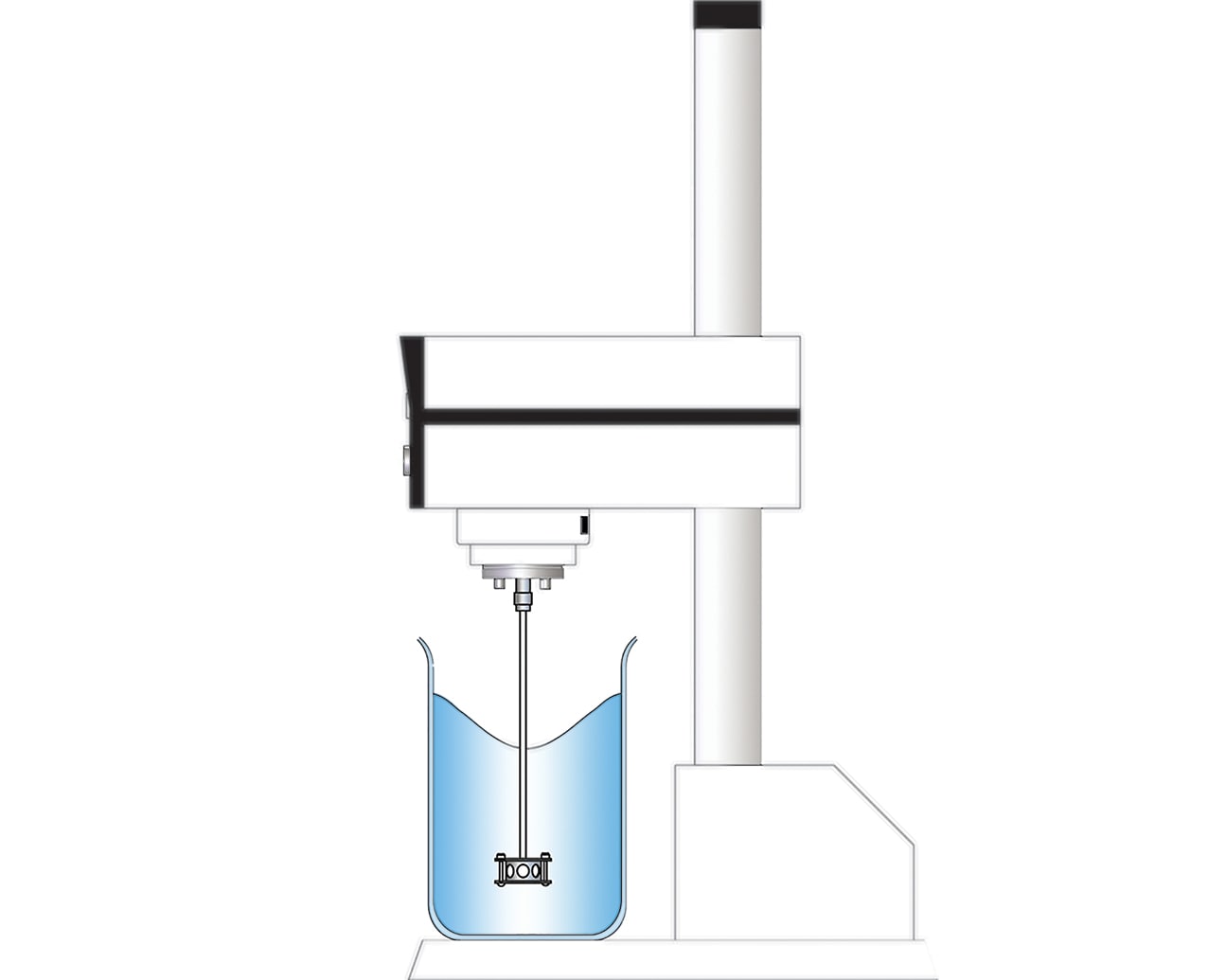

Laboratory Mixers

- Ideal for smaller batches and R&D work

- Suitable for batch sizes of up to 12 litres

- Built to the same tolerances as production models, providing easy and accurate means of scaling up

- Interchangeable workheads allow the unit to be adapted for a range of laboratory applications

Silverson Pilot Scale Mixers

- Features generally as Laboratory mixer above

- Suitable for batches of up to 50 litres, depending on viscosity

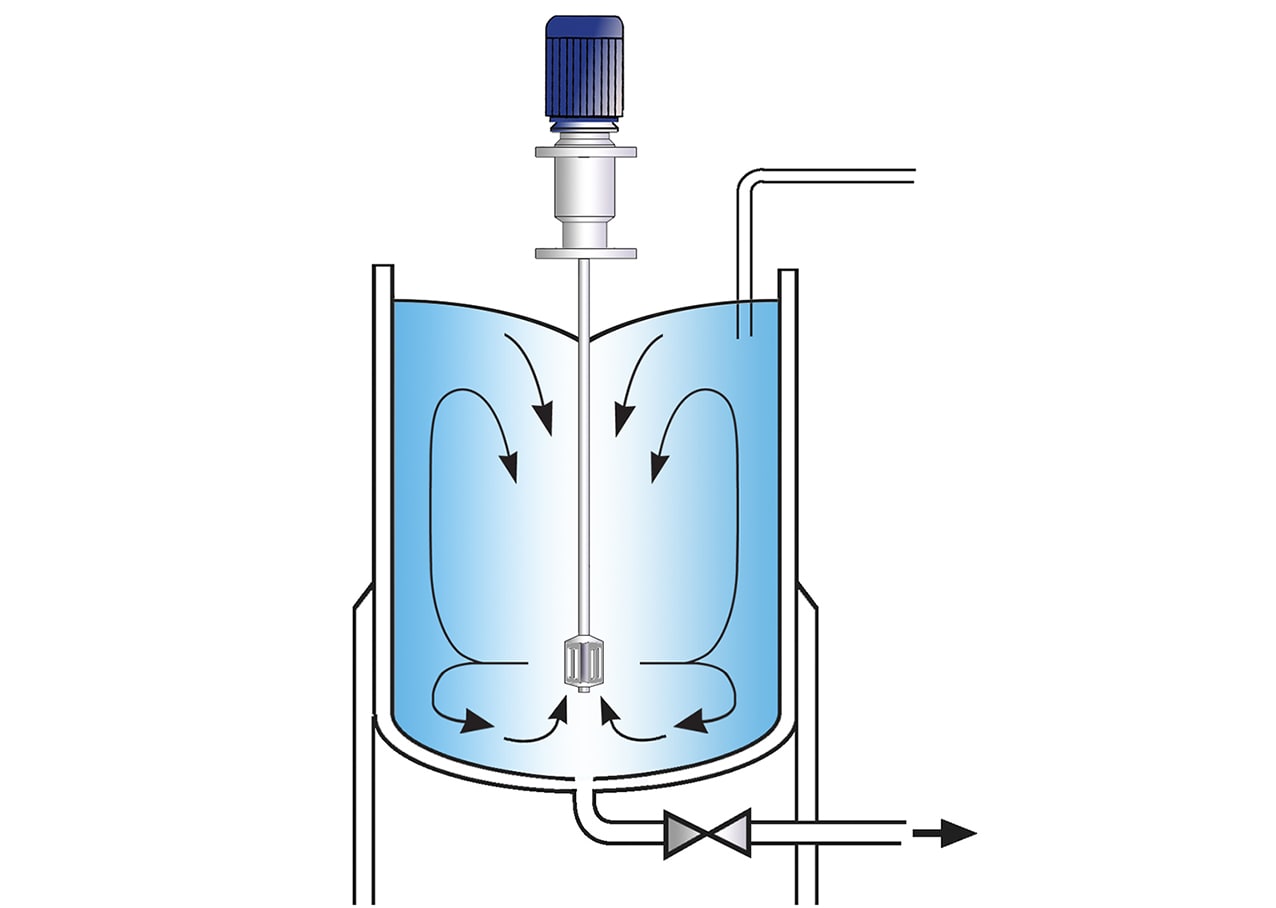

High Shear Batch Mixers

- Suitable for batches of up to 1000 litres

- Can be used on mobile floor stands

- Can easily be moved from vessel to vessel

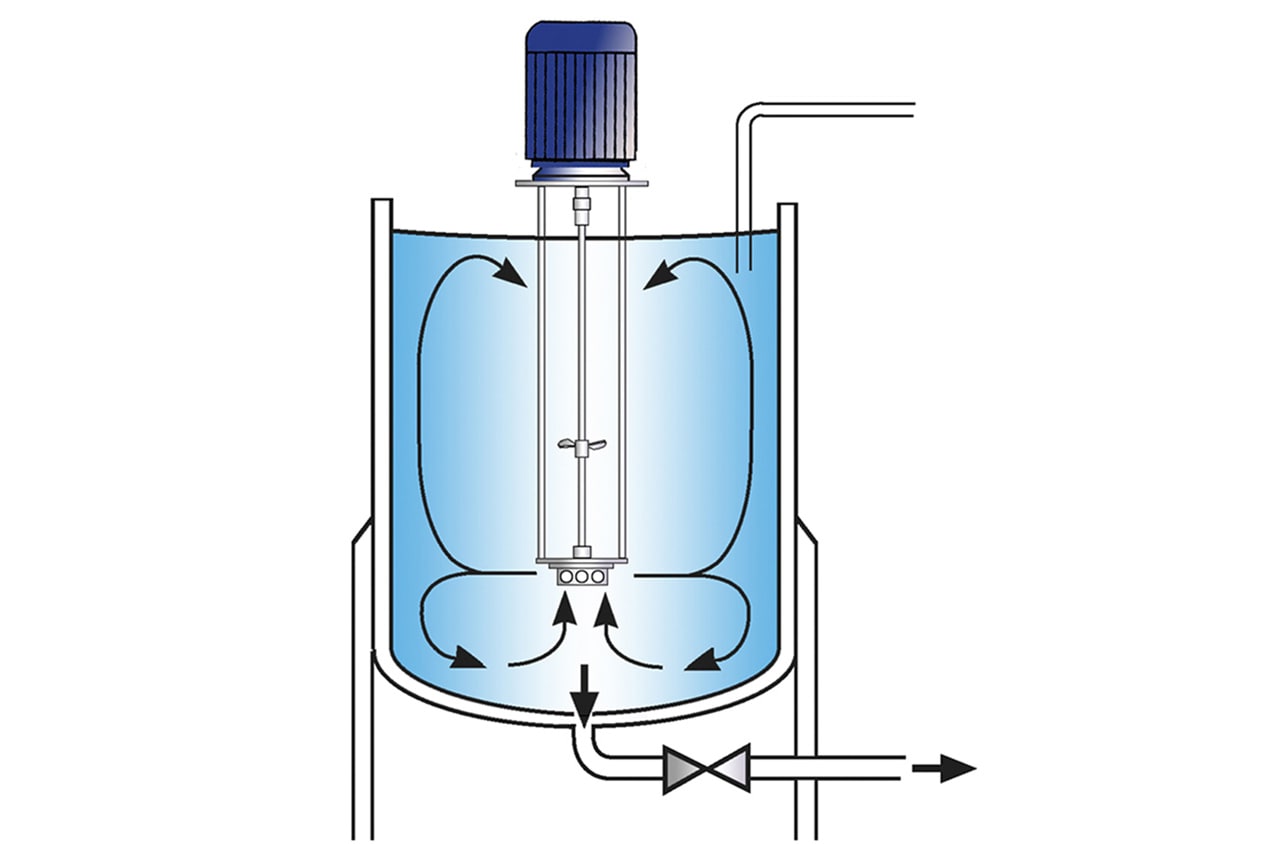

Silverson Ultramix

- Excellent in-tank movement

- Capable of rapidly incorporating large volumes of powders

- Ideal for higher viscosity mixes

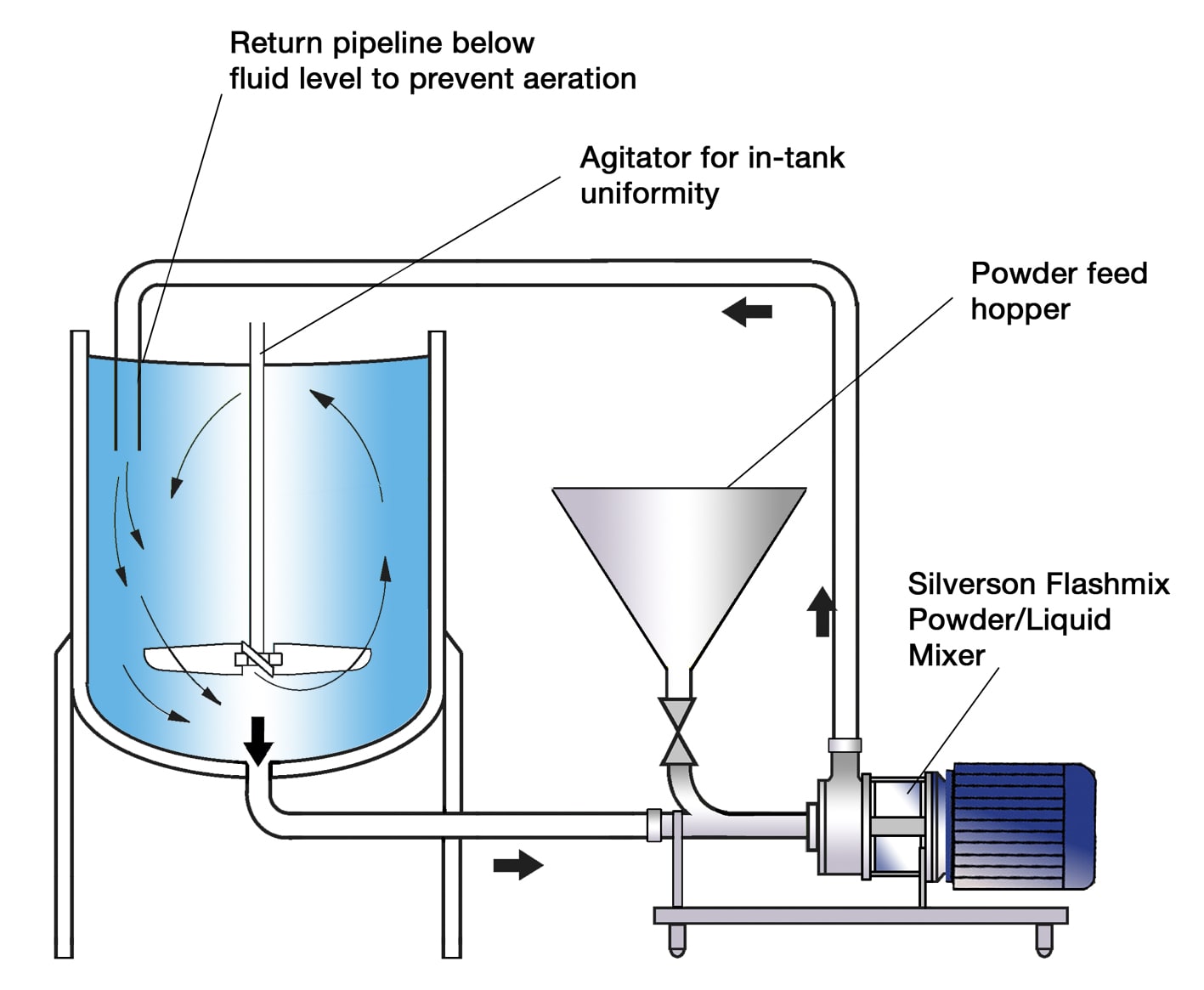

Silverson Flashmix

- Ideal for larger batches

- Capable of rapidly incorporating large volumes of powder

- Minimised aeration

- Minimised cleaning requirements

- Controlled powder addition rate

- Minimum operator input required

- Suitable for high viscosity mixes